Home > Products > kailitemachinery01 > SJSZ Conical Twin Screw Extruder

SJSZ Conical Twin Screw Extruder

- T/T

You May Like

Product Description

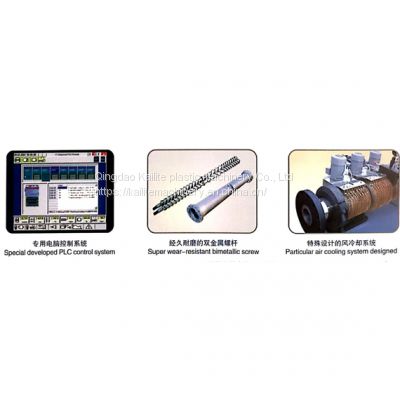

1. Gentle moulding design of SJSZ Conical Twin Screw Extruder guarantees the quality of the matter.

2. Dependable and valid design theory guarantees the dependable operation of extruding. The special big torque drive system, gear tooth and shaft are high-intensity alloy steel which are treated by the cementite and tooth grinding.

3. The fresh development screw may be applicable to the dispensation that has a great amount of padding and guarantee the degree of filling up and the optimum stuff distributing of material in a screw.

4. Screw with core temperature regulation unit and well barrel cool guarantees the exact control of technology temperature of the material.

5. Matched with a different standard of pipe die, the auxiliary device is used to extrude different pipe, plate, profile and soft and rigid PVC granulation.

he Parameter of SJSZ Conical Twin Screw Extruders

Main technique parameter ( conical twin screw )

ltem | SJSZ- 45*22 | SJSZ- 50*22 | SJSZ- 55*22 | SJSZ- 60*22 | SJSZ- 65*22 | SJSZ- 80*22 | SJSZ- 92*28 |

Screw diameter | 45/99 | 50/105 | 55/110 | 60/125 | 65/135 | 80/156 | 92/188 |

The screw rotates speed | 45 | 45 | 45 | 40 | 40 | 34.7 | 34.7 |

The biggest extruding capacity | 80 | 125 | 180 | 250 | 300 | 500 | 900 |

Main motor power | 18.5 | 22 | 30 | 30 | 37-55 | 55-75 | 132 |

Heat power | 15 | 18 | 20 | 20 | 28 | 35 | 85 |

Main technique parameter ( parallel twin screw )

ltem | SJSZ-65/26 | SJSZ-80/22 | SJSZ-90/26 | SJSZ-107/26 | SJSZ-130/26 |

Screw diameter | 65 | 80 | 90 | 107 | 130 |

The screw rotates speed | 50 | 33 | 45 | 10-30 | 10-30 |

The biggest extruding capacity | 160 | 250 | 330 | 600 | 1000 |

Main motor power | 22 | 22-30 | 55 | 90-100 | 110-160 |

Heat power | 18 | 24 | 38 | 52 | 85 |

Twin Screw Extruder Working Principle

1. Turn on the power. Adjust the temperature controller to a certain temperature and heat to temperature according to the process temperature controller to keep the material in the barrel soft for 3 hours, and then adjust the temperature controller for process temperature control.

2. Turn on the host when turning on the host, pay attention to the current of the motor. If the current is too large, the speed cannot be adjusted at this time. Check whether the material in the barrel is softened or whether the extruder is faulty. After waiting for it to be normal, adjust the speed to the speed required to produce the product.

3. Turn on the auxiliary feeder, tractor, and cutting machine.

Difference Between Single Screw and Twin Screw Extruder

1. The conical twin screw extruder china has excellent mixing capabilities because the intermeshing screws and a wide variety of professional screw designs allow precise adjustment of the degree of mixing to control the degree of mixing. On the other hand, the mixing capacity of a single screw extruder is very limited, and a special screw design is used to restrict the flow rate to enhance mixing.

2. The twin screw extruder china can handle a high level of process flexibility and the ability to handle multiple processes, such as melting, mixing, cooking, venting, cooling, etc. However, in the case of a single-screw extruder, the output and screw speed are dependent, and the screw design with multiple tandem processing functions is limited.

3. Compared with single screw extruder, twin screw extruder can provide higher process productivity.

4. The twin-screw extruder has a relatively high price due to the complex nature of the machine, while the single-screw extruder has a simple structure and low price.

5. The plasticizing capacity of the twin-screw extruder is better and faster. In a single-screw extruder, the granular material stays in the extruder for longer, which slows down the production time.

6. The twin-screw extruder has complex operation and higher process control requirements than single-screw extruders, simple operation and simple control process.

Kailite is a extrusion line manufacturer, we provide conical twin screw extruder design, conical twin screw extruder pvc, twin screw extruder price list and etc. Want to know twin screw extruder machine price or buy twin screw extruder? Please contact us.

Contact Us

- Qingdao Kailite Plastic Machinery Co., Ltd

- Contact namePeter Tai Chat Now

Product Categories

| kailitemachinery | 20211026 | kailitemachinery01 |

New Products

-

HDPE Corrugated Tube Production Line

-

HDPE Large Diameter Hollowness Wall Winding Pipe Production Line

-

HDPE Water And Gas Pipe Production Line

-

Kailite Plastic Extrusion Machinery

-

Automatic Drying And Feeding Machine

-

Automatic Plastic Mixer

-

Extrusion Line Auxiliary Equipment

-

Melt Blown Fabric Production Line

-

No Chip Plastic Cutting Machine

-

PE Foamed Sheet/Film Production Line

-

SJSZ Conical Twin Screw Extruder

-

SWP Series Crusher

Popular Searches

- extrusion machine

- production making machine

- line making machine

- profile making machine

- production machine

- profile extrusion machine

- extrusion line machine

- door frame making machine

- wpc profile machine

- plastic extruder machine

- profile extruder machine

- pvc profile extrusion line

- wpc extruder

- plastic profile extrusion line

- plastic profile production line

- door frame machine

- wpc production line

- wpc profile plastic machine

- door board production line

- wpc door profile

- wpc profile extrusion machine

- door frame production line

- pvc door frame machine

- wpc door frame line

Recommended Products

- Luoyang Sanyong Machinery Industry Provides a Wide Range of Rubber Roller Processing Specifications And Offers Professional Customization Services.

- High Precision In Mould Label Rubber Plastic Film Label Die Cutting Machine

- High Precision Rubber Plastic Sheet Calender Machine

- 3L-110L Industrial Standard Rubber Banbury Internal Mixer

- 6/9/10 Inch High Quality Lab Use Rubber Plastics Mixing Machine Open Mill

- Rubber PVC Patches 2/3D Labels Making Machinery

- PVC Rubber Patches 3D Keychain Making Machine

- YC-401 Automatic Glue Turning And Opening Mill

- New 30ton/50ton Lab Vulcanizer PLC Controlled Plastic Hot Press Machine for Rubber With Reliable Engine Pump for Manufacturing

- Small Factory Machine Pvc Label Patch 3d Keychain Refrigerator Fridge Magnet Maker Machine

- United Tech Machinery 4 Shaft Shredding Machine for The Msw Recycling System Waste Treatment Cuztomized Four Shaft Shredder

- Four Shaft Paper Shredder Carton Shredding Machine Secure Document Destruction Machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Rubber Machinery > Rubber Product Making Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Peter Tai

Hi there! Welcome to my shop. Let me know if you have any questions.

Peter Tai

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile