|

material |

100% polypropylene |

elongation at break |

30% |

|

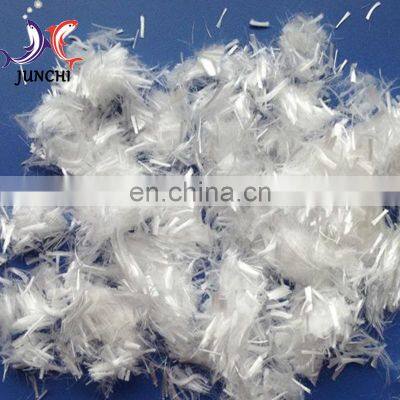

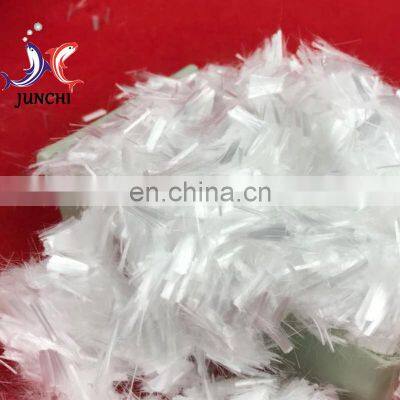

Fibre type |

Bunchy monofilaments |

specification |

3,6,9,12mm or customerize |

|

density |

0.91 |

tensile strength |

≥400mpa |

|

Acid and alkali |

High |

young modulus |

≥3.5Gpa |

|

Melting point |

About 160℃ |

fiber diameter |

31um |

|

conductivity for heat |

very low |

burning point |

580℃ |

|

Containing moist |

<0.1% |

safety |

Non-toxic materials |

|

Resistance low temperature |

Monotony -78℃ |

||

|

ageing resistance |

Anti- ageing resistance |

||

Package:

20KG per bag,1kg/inner bag.

600g/paper bag,6kgs/box.

The products should be stock indoor where is dry& well-ventilated, and prevent humid,avoid sun exposure.

The main purpose of polypropylene fiber are cement mortar,insulating mortar,putty powder. such as:

1,Improve the cracking resistance of mortar;

2, Improve the proof impermeability of mortar;

3,Improve shock resistance&seismic capacity.

4.Improve the bending strength, chemical resistance and alkali resistance of the final products.

5.In high class road construction, by using the fiber the tensile strength and tensile stress can be improved significantly.

6.To be anti-cracking material for concrete/mortar. By mixing with concrete/mortar not only the tensile strength of concrete is improved but the internal cracks of concrete are reduced and further development of micro-cracks is restrained.

7.The bundled uncut fiber can be used to replace rebar in application of water conservancy projects.

8.To be the reinforcement material of plastic products in applications of anti-explosive helmets.

9.To be the reinforcement material for rubber products and to produce conveyer belt, fire hose and woven hose.

Send Inquiry to This Supplier

You May Also Like

-

Glass Fiber Acrylic Fiber Polypropylene FiberUS$ 0.65 - 1.3MOQ: 500 Kilograms

-

Polypropylene Staple Fiber for Filtering YarnCNY 1.9 - 2.8MOQ: 8000 Kilograms

-

Polyester Staple Fiber Price pp Crimped Fiber for Concrete ReinforcementNegotiableMOQ: 1

-

HT 1100 Dtex Natural White PP Multifilament YarnNegotiableMOQ: 1

-

Polypropylene Monofilament Fiber For ConcreteNegotiableMOQ: 1

-

19mm Polypropylene Construction Fiber for Concrete ReinforcementUS$ 1.4 - 2MOQ: 1000 Kilograms

-

Dope Dyed Fiber PP Staple Fiber 3D*65MMUS$ 1.59 - 2.38MOQ: 1000 Kilograms

-

Junchi Non Woven Oil Absorb Pad Geo Textile Use Polypropylene Synthetic FiberUS$ 1,500 - 1,500MOQ: 2 Tons

-

Manufacturer PP Fiber, Polypropylene Staple Fiber 3d-70dUS$ 1.49 - 2.3MOQ: 300 Kilograms

-

High Quality Cheapest Price Gold Silk & Silver Silk PP Yarn For CarpetUS$ 2.1 - 2.9MOQ: 1 Ton