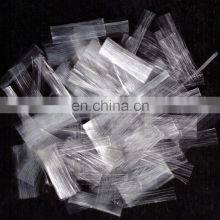

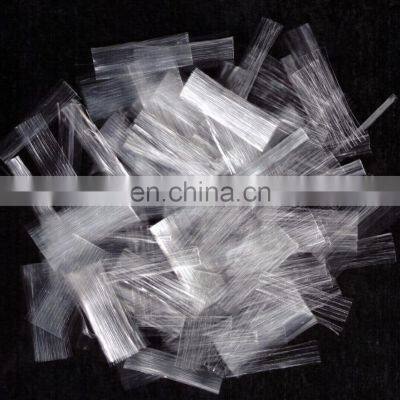

polypropylene fiber concrete

1.Use:

1.Roads, pavements, driveways, kerbs

2.Shotcrete, thin section walling

3.Overlays, patch repair

4.Most small builder, cash sales and DIY applications

5.Internal floor-slabs (retail stores, warehouses, etc.)

6.External slabs (driveways, yards, etc.)

7.Agricultural applications

8.Water retaining structures, marine applications

9.Security applications such as safes and strongrooms

10.Deep lift walls

2.Feature:

1) Increase the cracking resistance

2) Increase the seepage resistance

3) Improve tensile, bending & folding strength

4) High Anti acid & alkali performance

5) Suit for the waterproof layer, floor, inner & outer wall of industrial and civil construction

6) Suit for any mortar projects and common concrete projects

3.Description

Raw Material | Polypropylene |

Type | Monofilament/Mesh/multifilament |

Fiber Diameter | 10-45um |

Fiber Denier | 3-6D |

Tensile Strength | ≥500Mpa |

Size | 3mm |

Crack Elongation | 15-25% |

Density | 0.91g/cm3 |

Melting Point | 160---170℃ |

Resistance to Acid, Alkali | Strong |

Water Absorbency | No |

|

|

Packing | 600g/bag,900g/bag,1000g/bag, 20bag/pp bag or As customer's request |

Delivery | 20 days |

Payment | TT 30% advanced, 70% against BL copy LC at sight |

Sample | Sample free, express paid by customer |

MOQ | 1,000kg |

Customized | accept |

4.Producing

5.Customer Visit

6.construction technology

1.According to the volume of concrete, in accordance with the requirements for mixture ratio (or suggested dosage) to calculate fiber dosage.

2.After building stones of sand is ready, add the pp fiber. Recommend to use the forced mixer.

3.Add the pp fiber and aggregate into the mixer.But notice: fiber must been added between the aggregate,dry mixing 30s,add cement and water,wet mixture 30s, in order to make the fiber dispersed adequately.

4.Stir after the completion of the random sampling, such as fiber has evenly dispersed into monofilament, concrete can be put into use, if you still have bunch of fiber is extended mixing time 20-30 seconds, then concrete can be used.

5.Add fiber concrete with normal concrete construction and maintenance process is exactly the same.

7.Contact

Send Inquiry to This Supplier

You May Also Like

-

Quality PVC Interior Ceiling Panel Modern Design Fireproof Perforated Ceilings Easy Installation With Ceiling GridNegotiableMOQ: 1000 Square Meters

-

Premium PP Corrugated Sheets – Thickness Options for Industrial & Export ApplicationsNegotiableMOQ: 3000 Pieces

-

Factory Wholesale Supply Rain Water Drainage Plastic Pvc Rain Gutter Cover Roof Anti Leaf Rain Gutter GuardUS$ 1.53 - 1.74MOQ: 3000 Pieces

-

10mm Thich Hdpe Pe300 Extruding Plastic SheetUS$ 2 - 5MOQ: 1 Blade

-

Plastic Tube Steel Security Half Round Fence Post CapsUS$ 0.09 - 0.31MOQ: 1 Piece

-

High Quality Plastic Polypropylene Retort Separator SheetsNegotiableMOQ: 1

-

Super Clear Transparent Door Colourful PVC Strip Curtain Rolls PVC Door CurtainNegotiableMOQ: 1

-

SANHONG High Quality EVA Sheet Foam Supplier Roll EVA Mats ManufacturerUS$ 130 - 142MOQ: 28 Cubic Meters

-

Carrier Bag Making MachineUS$ 5,000 - 10,000MOQ: 1 Set

-

Eco-friendly Wine Holder Bag Felt Printed Christmas Logo Leather Cutting LogoUS$ 1.5 - 2MOQ: 200 Pieces