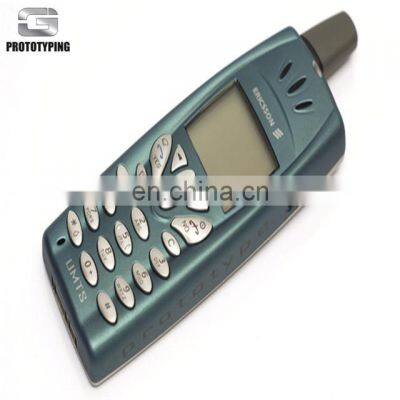

Custom Robot Shell Usb Charger Shell Plastic Box Plastic Electric Shells For Keypad Mobile Phone

Raw material | Plastic(ABS,PC,PP,PA,PMMA, PA+GF, teflon etc) and metal( Alu,SS,brass and copper) | ||||||

Work table size | 1200* 800* 300mm | ||||||

File format | IGS, STP, X-T | ||||||

Tolerance | 士0.1mm | ||||||

Software | ProE, Solidwork, UG, 3D Max | ||||||

Surface treatment | Polishing, electroplating, blasting, painting, and so on | ||||||

MOQ | 1 PCS | ||||||

Lead time | 1 day | ||||||

Packaging | Carton box or wooden case | ||||||

1. Getting your product 3d file ready

3. Case design shaping

4.First polishing

5.Surface treatment

6. Trial assembling

7. Prototype inspectiony

Q: How to get a quote?

A2: Please send your 3d drawing(STP, IGS, STL, OBJ, X-T...) to us, and tell us the material, surface treatment and quantity, then we will quote within 2 hours.

Q: Can I order one piece for testing?

A3: Yes.

Q: How long is your delivery time?

A4: 3 to 4 work days

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment.

Send Inquiry to This Supplier

You May Also Like

-

High Recovery Gold Washing Carpet Mining Alluvial Gold Moss Mat Grass Carpet Gold Mining CarpetNegotiableMOQ: 10 Rolls

-

LG PC/ABS Lupoy GN-5001RF Polycarbonate + ABS Resin Plastic Raw MaterialUS$ 1.5 - 2MOQ: 25 Kilograms

-

Bottle Sealing Lock Buckle Plastic Rings for Decorative Sealing BOLIUS$ 0.1 - 0.2MOQ: 10 Pieces

-

ZYTEL(R) ST801 NC010 Engineering Thermoplastic Resin With Superior Chemical ResistanceUS$ 5.6 - 6.6MOQ: 25 Kilograms

-

High-BARRIER Plastic Wear-Resistant and Chemically Resistant for Various Projects in POK M330A PolyketoneUS$ 3.72 - 3.88MOQ: 25 Kilograms

-

Hot Selling 5500m2/m3 MBBR Bio Filter Floating Media Biochip 30 for Ras AquacultureUS$ 150 - 480MOQ: 1 Cubic Meter

-

Pier Buoy Floating Box on Water Pontoon BridgeUS$ 12 - 15MOQ: 50 Pieces

-

16mm 19mm 25mm 38.1mm Round Square Tube End Leg Tip Plastic Pipe PlugNegotiableMOQ: 100 Pieces

-

Portable Pop up Privacy Shower Tent Spacious Changing Room for Camping Hiking Beach Toilet Shower BathroomUS$ 24.00MOQ: 1 Set

-

Shenzhen Runpeng Custom Injection ABS PP Plastic PartsNegotiableMOQ: 1