Aluminum Honeycomb Panel

Aluminum Honeycomb Panels

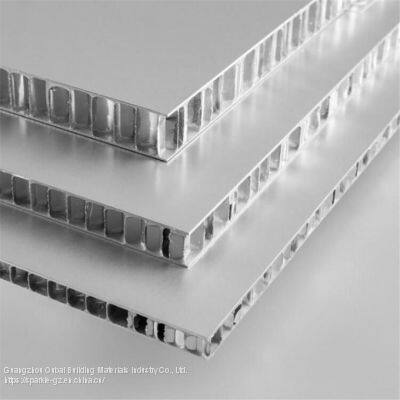

Structure: Aluminum skins + Aluminum honeycomb core + Aluminum skins.

1. Face Skin: Perforated aluminum plate;

2. Bottom Skin: Perforated or un-perforated aluminum plate;

3. Core: Aluminum honeycomb;

4. Adhesive: PU/ Epoxy glue or film;

5. Surface treatment: PVDF/PE coatings/ customized;

Packing Details: Standard pallets/ plywood cases/ cartons

Product description

Aluminum Honeycomb Panel is a kind of sound absorbing panel which composed of the perforated face skin and perforated or un-perforated bottom skin and aluminum honeycomb core.

Due to the honeycomb core in the aluminum honeycomb acoustic panel are divided into a large number of closed cells, the air flow is prevented and the sound waves are obstructed. When sound passes through acoustic panel, the intensity of sound is decreased and the sound absorption coefficient (can be up to 0.9 or more) is improved. In addition, it can provide more freedom for designers due to its excellent attributes such as high strength and light weight.

Below is our regular specifications:

Type | Material | Thickness | Surface Coating | Size | Color |

Aluminum Honeycomb Panel | Aluminum alloy | Standard thickness: 10,12,15,18,20, 25mm; Custom made available

| PVDF/PE coatings/ customized | Standard width:1220,1250,1500mm Length≤6000mm Width≤1500mm

| Black /Stone/Wood, Subject to user demand

|

Notes: Besides standard sizes, Sparkle aluminum honeycomb panel can be customized to meet your unique needs.

When the application requires a flat, rigid and lightweight work surfaces, aluminum honeycomb panels with aluminum facings offer flat, wear resistant surfaces that can be custom machined. Panels can have open edges or be closed out.

Features

1.Aluminum Honeycomb Panel bases on grade 3003 aluminum alloy sheet, and the aluminum sheet owns water - proof property. After PVDF coated on its surface, the whole panel has weather resistance, chemical preservation and etc;

2. When in installation, panels are tightly connected with sealed aluminum profiles from four sides, so as to prevent rainwater from osmosis;

3. Plug - in installation method & weather silicone sealant are applied to achieve the best water - proof effect;

4. Durable, Washable, Scrubbable, Mortar - resistant, Corrosion - resistance;

5. Custom made metal walls available to coordinate with ceilings and other interior / exterior finishings;

6. Certificate: ISO9001:2008, ISO14001:2004, CE, GB/T28001-2011, SGS Test etc;

Applications:

· Work surfaces and tables

· Wall panels

· Platens

· Machine enclosures

· Machining surfaces

· Furniture

· Custom table systems

· Fixtures

Send Inquiry to This Supplier

You May Also Like

-

Aluminum Corrugated PanelNegotiableMOQ: 1000 Square Meters

-

Aluminum Corrugated Panel AlloyNegotiableMOQ: 1000 Square Meters

-

Indoor Decoration Aluminum Corrugated PanelNegotiableMOQ: 1000 Square Meters

-

Promotion Price Aluminum Core Composite PanelNegotiableMOQ: 1000 Square Meters

-

High Quality Aluminum Core Composite PanelNegotiableMOQ: 1000 Square Meters

-

1100 Aluminum Core Composite PanelNegotiableMOQ: 1000 Square Meters

-

PVDF Coating Aluminum Core Composite PanelNegotiableMOQ: 1000 Square Meters

-

Wood Painted Aluminum Core Composite PanelNegotiableMOQ: 1000 Square Meters

-

Meshed Aluminum PanelNegotiableMOQ: 1000 Square Meters

-

Carved Aluminum PanelNegotiableMOQ: 1000 Square Meters