Shock Resistance UHMWPE CNC Parts, Wear Resistant Wheels

Products Description

Our advantages:

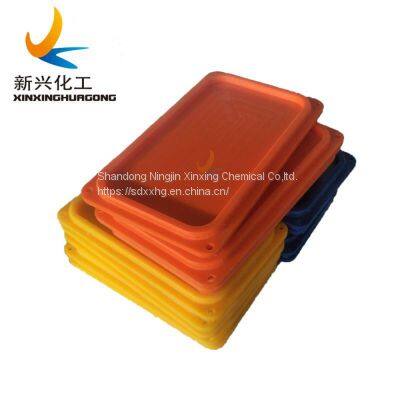

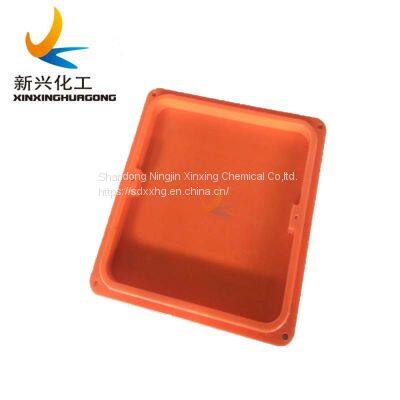

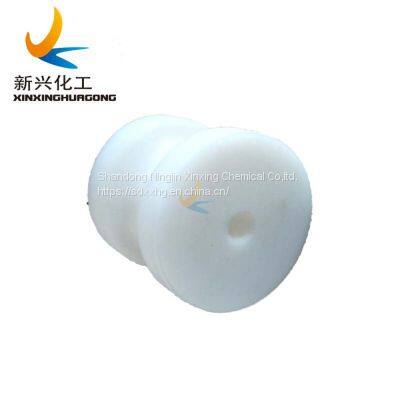

Material: UHMWPE/HDPE/PP/Nylon

Produce Procedure: CNC, Injection etc.

Shape: Any, according to the drawing

Size: Any size is available

Color: Black, White, Yellow, Green, Blue etc.

Fast shipment, short production time, superior quality

Here, we could meet all your requirements for customized plastic parts

very flat on the surface

The thickness tolerance is +2 -0mm,some made according to your requirements.

The color is pure and any color can be made by us.

We can give you an accurate size of UHMWPE Components with advanced machine.

Different shaped UHMWPE components also can be made by us like bending sheet.

According to different requirements with different application, special specifications can be customized, like anti-UV, fire-resistant,anti-static and with other characters.

Highest abrasion resistance of any polymer, 6 times more abrasion resistant than steel

Very low water absorption

Excellent impact resistance

Good corrosion & chemical resistance

Noise-absorption & Vibration-absorption

Excellent Chemical Resistance Machined UHMW Polymer Parts Application

1. Conveyor Paddle

2. Impact Bar

3. Dock Bumper

4. Pipe Support Block

5. Chain guide

6. Pulley and Roller

7. UHMWPE Saddle or Block

8. Machine wear block and strips

9. Other machined parts

Any size, Shape are available with us.

Advantages

Self-lubricating.

Good Abrasion&wear resistance (15 times more resistant to abrasion than carbon steel).

Corrosion & impact resistant.

low temperature resistant.

Non-water absorption

Easy to machine

| Property: | Test Method (Standard) | Ticona GUI4152 | Ticona GUI4150,4120 | Unit |

| Molecular weight | 3-9 million | 3-9 million | ||

| Density | ISO 1183-1:2012/DIN53479 | 0.92-0.96 | 0.93-0.96 | g/cm³ |

| Compression strength | ISO 604:2002 | ≥30 | ≥32 | Mpa |

| Tensile strength | ISO527-2:2012 | ≥20 | ≥22 | Mpa |

| Elongation at break | ISO527-2:2012 | ≥300 | ≥300 | % |

| Dynamic Friction coefficient | ASTM D 1894/GB10006-88 | ≤0.20 | ≤0.18 | |

| Dynamic Friction coefficient | ASTM D 1894/GB10006-88 | ≤0.20 | ≤0.18 | |

| Notched impact strength (Charpy) | ISO179-1:2010/GB/T 1043.1-2008 | ≥100 | ≥100 | kJ/m2 |

| Abrasion wear index | ES-X60210-2008 | ≤30 | ≤30 | mg |

| Vicat softing point | ISO306:2004 | ≥80 | ≥80 | °C |

| Hardness shore-D | ISO 868:2003 | 65 | 66 | D |

Our factory

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment

Send Inquiry to This Supplier

You May Also Like

-

UHMWPE Customized Wear Resistant Linear Guideways RailsUS$ 3 - 6MOQ: 300 Kilograms

-

HDPE Sheet UHMWPE 1000 L-Angle BarUS$ 9.7 - 10MOQ: 10 Pieces

-

UHMW PE 1000 Wear Strips & Parts Wear Strips & Wear Components | Plastic Machining CompanyUS$ 0.5 - 10MOQ: 1 Kilogram

-

CNC Routed UHMWPE Wear Resistant Parts From All PlasticsUS$ 5 - 10MOQ: 1 Kilogram

-

Machining UHMWPE UHMWPE Ultra High Molecular Weight Polyethylene 5% Boron Added UHMW PE PartsUS$ 5 - 10MOQ: 1 Kilogram

-

Engineering Plastic Products Factory Custom Pe1000 UHMW-PE Plastic Injection Mold High Quality UHMWPE Conveyor System ChainUS$ 0.5 - 10MOQ: 1 Kilogram

-

UHMW Polyethylene Plastic Track Pad for Milling Machine and Excavator Black Excavator UHMW Track PadUS$ 2.13 - 4.63MOQ: 300 Kilograms

-

New Era of Construction Machinery Crawler Materials Impact Resistant Black Color UHMWPE TRACK PADSUS$ 2.13 - 4.63MOQ: 300 Kilograms

-

Black Non-Toxic and Smell UV Resistance Excavator UHMW Track PadUS$ 2.13 - 4.63MOQ: 300 Kilograms

-

UHMWPE Plastic Parts Mechanical Handling Conveyor, UHMWPE PTFE Seal Ring for Food Processing MachineryUS$ 0.5 - 10MOQ: 1 Kilogram