Biogas Energy Plant & AD(Anaerobic Digestion) Plant Waste Solution Project Anaerobic Digestion System

Biogas Energy Plant & AD(Anaerobic Digestion) Plant Waste Solution Project Anaerobic Digestion System

Peaks-eco is one of the largest suppliers of bioenergy systems in China. The expertise of Peaks-eco focuses on the technological development of the processing of biomass streams and the supply of systems for renewable energy from biomass. Peaks-eco supplies anaerobic digesters for agriculture and industry, biogas upgrading systems, biomass and waste-fired boilers, combined heat and power plants and fluidized-bed gasifiers.

In addition to the supply of complete plants, Peaks-eco has developed a wide range of components for the optimization of bioenergy systems. With over 20 years of experience in the design, construction, and installation of biogas plants, biomass-fired CHP’s and a large service team throughout China, Peaks-eco is your ideal partner in the field of bioenergy systems.

How a plant works?

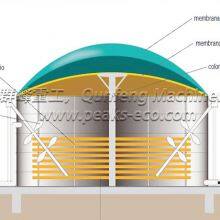

Through a loading process, the biomass that is to be treated is fed into a digester.Digesters are tanks made of reinforced concrete that can be round or rectangular.The main activity - anaerobic digestion (when biomass is converted into biogas) takes place within the digester.

The biogas formed is sent to a gasometer (a pressure-switch accumulator for biogas) which absorbs any production variations. This ensures that the power supplied is regulated by the pace at which the biogas is produced.

Once the biogas reaches the cogenerator (engine) it is transformed into:

Electrical energy, which is transferred to the national grid.

Thermal energy, used to maintain the process temperature constant and also to heat of some premises (e.g. homes, offices, greenhouses ...).

The remaining waste left over from the entire process is called digestate and is made up of solid and liquid manure.

This by-product can be used as an excellent fertiliser and can be used on fields instead of chemical fertilisers.

The advantages of Peaks-eco at a glance:

Flexibility of use

Whether in the home, as a carbon-neutral fuel (CNG) for the transport sector or converted on-demand into electricity and heat, Peaks-eco is a true all-rounder that can also be used in a decentralised system

Independent

Peaks-eco frees us from our dependence both on fossil natural gas and natural gas importers, thereby helping to support predictable long-term pricing trends in domestic energy market.

Excellent public acceptance

Peaks-eco is renewable. This means heating consumers benefit from an improved CO2 footprint and potential savings resulting from the more efficient use of energy. As a highly efficient fuel, Peaks-eco is also a star performer in the fuel market and can help to reduce emissions many times over.

Strong market potential

Since crude gas sources and gas grid infrastructure are both available, neither time nor capital investment is necessary to establish them. On the contrary: the use of Peaks-eco can unburden the electricity network and contribute to a temporary easing of cost-intensive upgrading work.

Regional value chains

Peaks-eco promotes economic growth both in the feed-in region – which is in the immediate vicinity of the gas generating plant – and in the consuming region, which is independent of the feed-in location.

An additional pillar for your business

Since our gas upgrading systems are exceptionally efficient and cost-effective, they can offer biogas plant operators another attractive source of revenue from Peaks-eco production.

/Biogas-energy-plant-AD-plant/Biogas-Energy-Plant-AD-Plant-53.html

Send Inquiry to This Supplier

You May Also Like

-

Vertical Waste Transfer Station ProjectUS$ 1 - 100MOQ: 1 Set

-

Horizontal Waste Transfer Station ProjectUS$ 1 - 100MOQ: 1 Set

-

FDY-1250 Full Automatic Baler Machine,baler Machine for Paper,paper Baler MachineUS$ 1 - 100MOQ: 1 Set

-

Waste to Energy System,waste Treatment System,waste Sorting PlantUS$ 1 - 100MOQ: 1 Set

-

Waste Sorting Plant,waste to Energy System,waste Treatment SystemUS$ 1 - 100MOQ: 1 Set

-

Waste To Energy (RDF&SRF),waste Sorting Machine,waste Sorting Plant,waste Sorting MachineUS$ 1 - 100MOQ: 1 Set

-

Waste Sorting System for Municipal and Household Waste,waste Sorting SystemUS$ 1 - 100MOQ: 1 Set

-

Material Recycling Factory (MRF),waste Recycling Machine,waste Recycling SystemUS$ 1 - 100MOQ: 1 Set

-

Biogas Energy Plant & AD(Anaerobic Digestion) Plant,waste Sorting Plant,recycling Sorting MachineUS$ 1 - 100MOQ: 1 Set

-

Waste Sorting Plant,waste Sorting Machine,herizontal Baler MachineUS$ 1 - 100MOQ: 1 Set