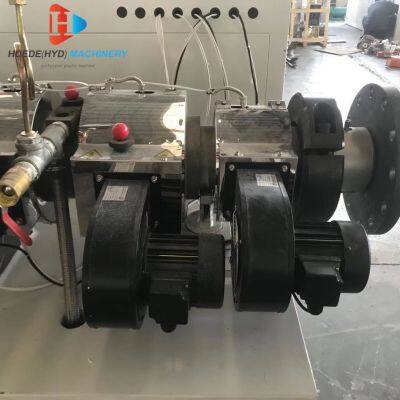

SJSZ51 Double Screw Plastic PVC PP PE Extruder Machine For Pipe Edge Banding Wall Ceiling Panel Making Machine

Product Description:

As a Plastic Extruder, plastic bag extruder machine is used in plastic processing industry. What are its principle andstructure? Next from the conveyor section of the extruder, compression section, metering section to make an analysis of the principle ofplastic filament extruder machine.

The effective length of PE extruder is generally divided into three sections. The effective length of the three sections is determined according to the screw diameter, pitch and screw depth, generally divided by one third of each section.High efficiency single screw extruder adopts two-stage overall design to strengthen plasticizing function, ensure high-speed,high-performance and stable extrusion, special barrier comprehensive mixing design, ensure the mixing effect of materials, high shear, low melting and plasticizing temperature ensure high-performance, low-temperature and low-pressure metering extrusion of materials. Design concept and features: high speed and high yield Extrusion Based on high flatness and straightness.

Product Images:

Machine Parameter:

| Items\Model | SJSZ51 |

| Diameter(mm) | 51/105 |

| Number of screw | 2 |

| Screw direction | Different to the outside |

| Screw Speed(r/min) | 5~35 |

| Effective Length of Screw(mm) | 1240 |

| Main motor power(kw) | 18.5 |

| Output(max)kg/h | 50-150KG/HR |

| Centre | Screw quantitative |

| Centre Height of marrel | 1000 |

Factory View:

Our Service:

All equipment, including parts and components, shall be guaranteed for 24 months, and any problem within the warranty period shall be replaced free of charge (except screw and barrel).

Send Inquiry to This Supplier

You May Also Like

-

PVC Wall Panel Making Machine Ceiling Panel Making Panels Production LinesUS$ 20000 - 40000MOQ: 1 Set

-

Double Cavity PVC Edge Banding Making Machine PVC Making Automatic Production LineUS$ 12000 - 16000MOQ: 1 Set

-

50~110mm Water Drain PVC PE PPR Pipe Extruder Machine Pipes Extruder Tube Making MachineUS$ 28000 - 33000MOQ: 1 Set

-

16~32mm Four Cavity PVC Plastic Pipe Making Machine Industry Pipe Plastic PriceUS$ 40000 - 55000MOQ: 1 Set

-

Four Cavity PVC Electrical Conduit Pipe Making Machine Price PVC Resin Material 16-32mmUS$ 40000 - 55000MOQ: 1 Set

-

Plastic PVC PE Corrugated Pipe Making Machine PVC PE Pipes Price Production LineUS$ 13000 - 16000MOQ: 1 Set

-

PVC Edge Banding Making Machine PVC Making Double Cavity Automatic Production LineUS$ 12000 - 16000MOQ: 1 Set

-

Three Layers PPR Pipe Making Machine PPR PE PVC Pipes Extrusion LineUS$ 30000 - 38000MOQ: 1 Set

-

16~40mm PVC Pipe Making Machine Two Double Cavity PVC PE Conduit Pipe Extruder Production LineUS$ 28000 - 45000MOQ: 1 Set

-

SHR Series High Speed Hot Mixer Machine Hot Mixing Machine For Plastic Powder PelletsUS$ 5000 - 6500MOQ: 1 Set