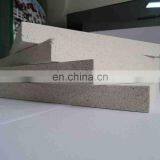

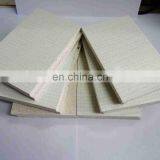

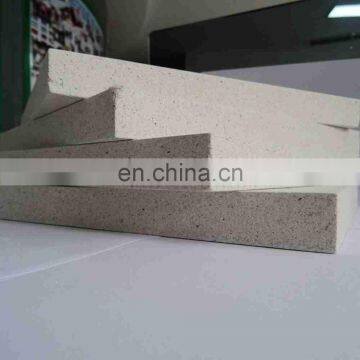

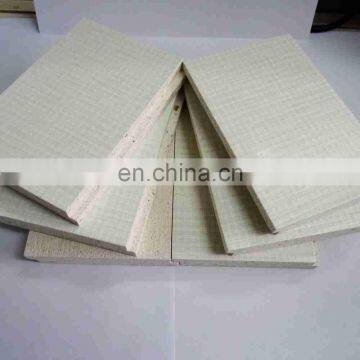

Mgo board

MGO board is made of magnesium oxide, magnesium chloride,and water. After configure and adding additives, stable performance of magnesia gelled material, with alkali glass fiber network in reinforced material, lightweight materials as filler compound and into a new type of incombustible decorates material. Adopting special production process, fire protection, waterproof, tasteless, non-toxic, not frozen, not corruption, not crack, unchanged, non-combustible, high strength light weight, convenient construction, long service life, etc

Quick Details

Place of Origin: ShanDong, China (Mainland) Brand Name: Yurui Model Number: 1220*3050mm

Product name: fireproof mgo board Raw material: MgO,MgS04, Fiberglass,etc. Certificate:SGS ISO

Size:1200mm*2400mm/3050mm×1220mm Thickness:3-20mm Fireproof Grade:Fire resistant Class A1

Surface density :0.85-1.5t/m3 Color:White, Grey ,Green,etc. Usage:Wall Partition,ceiling,etc.

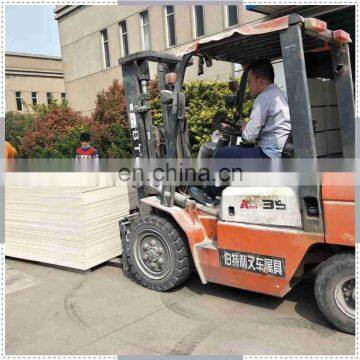

Packaging & Delivery

About Fireproof material mgo board:

In wooden pallet:6 flat pallets and 2 stand pallets in 1*20'GP.

If you need special packing,please tell me.

Delivery Time :15-20 days after the deposit

Outstanding fireproof performance

2. Flexible and easy to make proper sculpt and designs

3. Perdurable and great duration of life

4. Antisepsis mmothproof ,ant proof

5. Heat preservation ,heat insulation ,sound insulation

6. scientific prescrption ,real green and environmental material

7. 100% no Asbestos Contained

8. It is applicable to other designs of decoration and quadric process

Usage

The Mgo board is widely adoptable to partition and suspended ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation,sound insulation wall, places with dampness, mobile partition, special classfire prevention, sandwiched plate in fireproof gate and packaging of equipment cases

Due to the increasing quantity requirements of our boards, now we are building a new factory. We build the new factory with the newest high automatic machine, also will running under the new technology, producing sulfate MgO board.

Product Line

Mgo board equipment adopts double drive to roll extrusion process, the product from the slurry feeding, the main ingredient, spread the cloth, compound, complex pressure one-time finish whole production process, equipment of high degree of automation, stable operation, specifications adjustable. Product surface level off, smooth, high density, truly realized the industrialization of the new decoration plate production line. Greatly reduces the labor intensity of workers. Removing the disadvantages of mold casting model in the past

Why the cost of magnesium sulfate board is higher than that of magnesium chloride board?

The cost of the Non-chloride mgo board is around 8%-10% higher than chloride board, because there is lots strict requirement for the quality of Mgo powder and the temperature & humidity control is much more strict than chloride mgo board. Maybe some suppliers said the price of Chloride and Sulphate board is same, that is mainly because they do not use Pure sulphate mgo board, but mix the chloride with Sulphate, so the cost decreased a lot.

The specification of Grey Mgo board and the advantage of grey magnesium-glass board compared with cement fiberboard

Thickness: 3mm-20mm

Density: common gray color mgo board 950-1000kg/m³; sanding gray color mgo board 1000-1200kg/m³

Actually all these specification of gray color mgo board is same to white color mgo board, the only difference is that during producing, we put some color paste in it.

So why some customer need gray color mgo board ?

I would like to share with you some info about our Brazil customer, because now they use large quantity gray color mgo board.

Before, the Brazil customer purchased large quantity fiber cement board before, later they noticed that there are some advantage of mgo board than fiber cement board as follows:

1. the bending strength and flexibility is better

2. Application: mgo boad is easy-cut, easy screw, fiber cement board is relatively hard, when want to screw,

has to drill the hole first

So now they choose use gray color mgo board.

Send Inquiry to This Supplier

You May Also Like

-

Fully Automatic 3 Ply Nonwoven Fabric Disposable Medical Facemask Facial Surgical Face Masks Making Machine Production LineNegotiableMOQ: 1

-

Factory Manufacture Melt Blown Fabric MachineUS$ 72,000 - 72,000MOQ: 1 Set

-

Low Cost High Quality Slitting Nonwoven Fabric Cutting MachineUS$ 11,000 - 14,000MOQ: 1 Set

-

Automated Surgical Gown Making MachineUS$ 20,000 - 20,000MOQ: 1 Set

-

Machine Spot Welding Equipment Face Mask Welding Elastic Mask MachineUS$ 10,000 - 90,000MOQ: 1 Set

-

Dongguan Disposable Medical Outside Ear Loop Anti-Dust Face N95 M-a-s-k Making MachineUS$ 200,000 - 350,000MOQ: 1 Set

-

Plain Red Velvet Flock Fabric for Packaging Gift Box Fabric Material , Flocking FabricsNegotiableMOQ: 1 Set

-

Needle Machine /needle DetectorUS$ 0.0001 - 0.0001MOQ: 1 Set

-

2L Automatic Adjustable Time Centralized Lubricant Felting MachinesUS$ 50 - 150MOQ: 1 Piece

-

Regenerated Cotton Machine EquipmentUS$ 5,500 - 8,500MOQ: 1 Set

Recommended Categories

Explore top categories and find suppliers for your specific needs-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.