Hot Sale Low Pressure Polyurethane Foam Steering Wheel Making Machine

Product Purpose:

This machine used for Car seat cushions, furniture cushions, pillows, deflectors, instrument panels, sun visor, motorcycle cushions, bicycle cushions, insulation materials, refrigerators, refrigerated trucks, roof insulation panels, cushions, office chairs, handrails, furniture, decorative materials etc.

Product Characteristics:

Easy to maintain and operate; highly efficient under any production situation; simple and efficient; self cleaning; cost saving; direct material calibration at measurement; high mixing Precision; good repeatability and evenness; accurate material mixing ratio control.

Main Technical Parameters:

Model | Output Volume(g/s) | Material Pot Volume(L) | Mixing Ratio(P:I) | Total Power(KW) |

LZ-907A | 65-250 | 250 | 100:35-65 | 18 |

LZ-907B | 108-450 | 250 | 100:35-65 | 22 |

LZ-907C | 266-1330 | 250 | 100:35-65 | 26 |

LZ-907D | 520-2620 | 250 | 100:35-65 | 55 |

LZ-907E | 1050-5230 | 250 | 100:35-65 | 110 |

Feature:

The machine have handwork/automatism function, dry/wet injection choice function, automatic circle function, point move function, driving motor self-stop function. Handwork and dry injection are used to testing. In the normal working condition, choose the wet injection automatic function condition.In Weekend ,automatic circle function mainly apply to keep the system in the normal technics condition when the machine stop produce for a long time. Point move function aim at the high rigidity foaming material, prevent the washing pole stopping. Driving motor self-stop function aim at the intermission produce customer, in order to reduce the power cost and extend the machine’s life. All function data are operated on the operation menu. The control system have the strong malfunction alarm function, display all inspecting malfunction on the operation menu, having the voice and light alarm, the machine will automatic stop when urgency.

Q: Are you a trading company or a manufacture factory?

A: 100% Manufacture factory, welcome to visit our factory.

A: Yes, for sure.

Q: What forms of payment do you accept?

A: We accept payment by T/T, LC.

Q: How about after- sale service?

A: We will send professional engineers to final customer's factory for machine installation, commissioning and careful working training. The final customer will afford related cost .

Send Inquiry to This Supplier

You May Also Like

-

PU Foam Pouring Moulding Machine Polyurethane Foaming Injection Production LineUS$ 2000 - 4000MOQ: 1 Set

-

Pillow Polyurethane Foaming Machine Memory Foam Pillow MachineryUS$ 2000 - 4000MOQ: 1 Set

-

Bicycle Seats Sponge Foaming Machine With pu Automatic Production LineUS$ 2000 - 4000MOQ: 1 Set

-

Polyurethane Pneumatic Round Rotary Production Line, Silicone Cushion Automatic Turntable Production LineUS$ 2000 - 4000MOQ: 1 Set

-

Polyurethane pu Toy Low Pressure Foam Machine Carousel Conveyor Type Production LineUS$ 2000 - 4000MOQ: 1 Set

-

High Pressure Polyurethane Foam Injection Making Machine Sponge Making MachineryUS$ 2000 - 4000MOQ: 1 Set

-

High Pressure pu Injection Foam Machine Pu High Pressure Sponge MachineUS$ 2000 - 4000MOQ: 1 Set

-

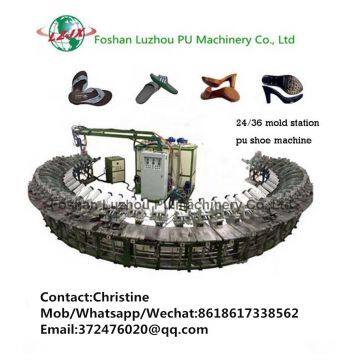

Semiautomatic Two Colors Two Density Safety Boots Snow Shoes pu Shoe Sole Injection MachineUS$ 2000 - 4000MOQ: 1 Set

-

Full Automatic pu Shoe Sole Making Machine Footwear Pouring Production Line pu Sport Shoe and Safety Shoe Molding MachineUS$ 2000 - 4000MOQ: 1 Set

-

36 Stations pu Sneaker Sole Injection Manufacturing MachineUS$ 2000 - 4000MOQ: 1 Set