BeO Ceramic Substrate Manufacturer in China/High Thermal Low Dielectric Beryllium Ceramic Substrate

BeO ceramic materials are ideal in thermal management applications when product design considerations include:

Miniaturizing the physical size of the device or enclosure

Exposing the component to high ambient temperatures

Airflow or liquid cooling is not possible or is prohibitively expensive

Applications that require a ceramic which insulates against electricity

Melting and sintering operations at very high temperatures for crucibles

BeO CERAMIC SUBSTRATE STANDARD SIZE

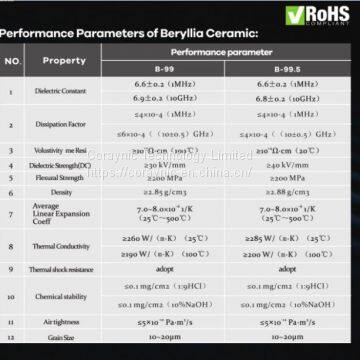

High thermal conductivity and low dielectric constant are the real reasons that BeO materials were widely used in electronic technologies, BeO ceramic is currently used in high-performance, high-power microwave packages, BeO substrates have also been used for high circuit density multi-chip components, Use BeO material to dissipate the heat generated in the system in time to ensure the system stability and reliability.

Metalized thick film lithographic substrates on BeO substrates well suited for high-reliability high-density microwave circuits. These substrates can be Working under conditions above 44 GHz for Tel-communications, live broadcasts, Satellite communication modules, mobile phones, personal communication services, base stations, advanced avionics, and Global Positioning System (GPS). Size can be and space scales as small as 0.001 inches, and routinely mounted in 4 x 4 Inches on the substrate. SiC reinforced aluminum metal matrix composites combined with DBC- BeO substrate has been successfully used for high current IGBT (insulated gate bipolar transistor). The design of the module substrate. Al/ SiC material combines high heat Dissipative, low aluminum alloy density and low coefficient of thermal expansion, and BeO The substrate is matched so that the thermal stress at the joint is reduced.

Why choose Coraynic Technology

--Sufficient supply

--Completive price

--Excellent performance

--Good service

--Top-quality raw material

--Prompt delivery

Our team can assist with selecting an optimal product for your RF and microwave microelectronics packaging. Contact our engineers for the best solution!

Send Inquiry to This Supplier

You May Also Like

-

99.5% BeO(beryllium Oxide) DISKUS$ 0.5 - 10.5MOQ: 10 Pieces

-

Beryllium Oxide(beo) Ceramic PartsUS$ 1 - 10MOQ: 1 Piece

-

BeO Beryllium Oxide Ceramic BarUS$ 1 - 2MOQ: 1 Piece

-

Beryllia/Beryllium Oxide/BeO Plate/substrateUS$ 1 - 10MOQ: 1 Piece

-

Beryllium Oxide/Beryllia Ceramic Structure/partUS$ 1.00 - 1.00MOQ: 1 Piece

-

Beryllium Oxide/beryllia/BeO Ceramic StructuresUS$ 1 - 10MOQ: 1 Piece

-

Beryllium Oxide/beryllia/BeO Ceramic ProductsUS$ 1 - 10MOQ: 1 Piece

-

Beryllium Oxide/beryllia/BeO Ceramic PartsUS$ 1 - 10MOQ: 1 Piece

-

Beryllium Oxide/beryllia/BeO Ceramic SubstratesUS$ 1 - 10MOQ: 1 Piece

-

Beryllium Oxide/beryllia/BeO Ceramic DiscsUS$ 1 - 10MOQ: 1 Piece