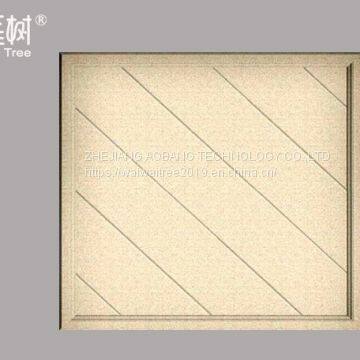

Aobang composite Wall Panel is divided into: BMC Wall Panel, SMC Panel, GRP Wall , GFK Wall Panel.

Composite Wall Panel the main functions: use imported silver ion, special effect antibacterial; energy saving; anti-corrosion, waterproof and moisture proof, mildewproof, fireproof; no harmful substances, no formaldehyde; easy to clean and maintain; scratch resistant; can be repeatedly disassembled, easy to repair; low carbon Environmental protection, surface diffuse reflection and energy saving; can be recycled, the economical applicability of building materials, high cost performance; beautiful appearance.

Established in 2010 and located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province, Zhejiang Aobang Technology Co., Ltd. has extensive bulk molding compound process and many refined testing laboratories as a spinal column in the industry. Whether at home or abroad, Zhejiang Aobang Technology Co., Ltd. can manufacture top quality bmc compound molds with advanced mold making concept, proprietary application technology and production technology. By the way, being a high-tech enterprise, it is a fact that this company enjoys a good fame in the new motor and energy automobile industry in Hangzhou.

SMC and BMC composite require heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Send Inquiry to This Supplier

You May Also Like

-

Auto Parts MouldUS$ 1 - 1000MOQ: 1 Piece

-

BMC/SMC Motor DescriptionUS$ 1 - 1000MOQ: 1 Piece

-

BMC/SMC MouldUS$ 1 - 1000MOQ: 1 Piece

-

Flange MoldingUS$ 1 - 1000MOQ: 1 Piece

-

BMC/SMC ProductsUS$ 1 - 1000MOQ: 1 Piece

-

BMC, SMC, GRP, GFK Building & Decoration MaterialsUS$ 1 - 1000MOQ: 1 Piece

-

BMC, SMC, GRP, GFK CeilingUS$ 1 - 1000MOQ: 1 Piece

-

BMC, SMC, GRP, GFK Roof TilesUS$ 1 - 1000MOQ: 1 Piece

-

BMC, SMC, GRP, GFK Wall PanelUS$ 1 - 1000MOQ: 1 Piece

-

BMC/SMC InsulationUS$ 1 - 1000MOQ: 1 Piece