Waste to Fuel Pyrolysis Machine Continuous Plastic Recycling to Plastidiesel Production Plant

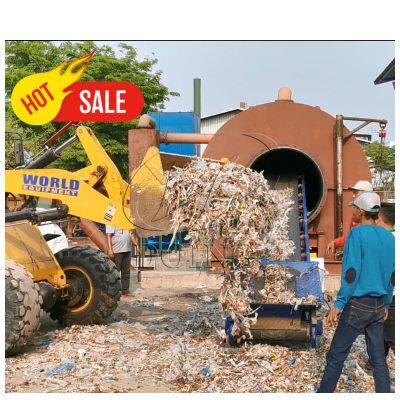

For latest technology continuous waste tire/plastic pyrolysis to fuel plant in Ghana main raw material is waste plastic, which can be easily available in and part of the world. The raw material, waste plastic is cheaper, and we get fuel oil, carbon black, as the end product. waste plastic continuous pyrolysis plant is feasible in technology with small amount of invement, high availability of materials, short recovery period and with bright future, is the ideal choice of investment.

1. Feeding in every second and minute,automatic ejiecting wastes residue,Fuel product day and night

2. High efficiency fully continuous plastic recycling to fuel oil pyrolysis plant with zero pollution, advanced technology, full automation.

3. Large capacity(10-30tons tire/plastic per day), high oil yield, good oil quality, high profit.

4. Low cost in operation. No need energy to heat the reactor, generated syn gas is enough, less manpower.

5. High quality and environment, to meet your strict emission standards.

6. Safety. Mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, guarantee 100% safety in the continuous tyre to oil recycling process.

whatsapp/wechat: +86 13526692320

Email:oilmachine@wastetireoil.com

Send Inquiry to This Supplier

You May Also Like

-

Continuous Fully Automatic Waste Tyre Pyrolysis PlantUS$ 50,000 - 150,000MOQ: 1 Set

-

Fully Continuous Waste Tyre to Fuel Oil Pyrolysis PlantUS$ 50,000 - 150,000MOQ: 1 Set

-

New Design 2022 Continuous Type Waste Tyre/plastic Pyrolysis Plant Recycling MachineUS$ 50,000 - 150,000MOQ: 1 Set

-

Great Quality Fully Automatic Continuous Car Tyre Pyrolysis Plant Waste Tyre Pyrolysis MachineUS$ 50,000 - 150,000MOQ: 1 Set

-

15-50T Fully Automatic Continuous Used Tire Pyrolysis System Waste Tyres to Oil Pyrolysis PlantUS$ 50,000 - 150,000MOQ: 1 Set

-

DOING New Design Fully Automatic Continuous Waste Tire Pyrolysis Plant in IndonesiaUS$ 300000 - 500000MOQ: 1 Set

-

DOING Newest Generation New Fully Continuous to Liquid Fuel Waste Tire Pyrolysis Plant Recycing MachineUS$ 300000 - 1000000MOQ: 1 Set

-

How to Deal With the Waste Plastic in Kazakhstan?US$ 200000 - 1000000MOQ: 1 Set

-

High Efficiency Fully Continuous Plastic Recycling to Fuel Oil Pyrolysis PlantUS$ 300000 - 500000MOQ: 1 Set

-

High Output Waste Plastic to Fuel Oil Pyrolysis Plant Small BigPlastic Pyrolysis UnitUS$ 28000 - 58000MOQ: 1 Set