Baoying Canal Forming Machine Side Ditch Sliding Form Machine Full-automatic Canal Forming Machine

Self-propelled U-shaped trough forming machine Farmland canal reconstruction equipment of self-propelled gutter forming machine

The canal bottom lining machine consists of four parts: feeding machine, spreading machine, trowel machine, and folding frame. The feeder is placed on the canal slope, the frame is connected with the spreader frame, and there are walking wheels at the bottom of the frame for traction and automatic control of walking. Evenner, trowel and noodle collecting frame are placed in parallel at the bottom of the canal, keeping a distance between them. The materials are put into the hopper of the feeder by the tanker, sent to the hopper of the leveler with the belt, then fed along the belt of the leveler, introduced into the storage hopper through the baffle plate on the belt, evenly spread by the vibrating plate below the frame, leveled by the trowel, and manually collected by the noodle collecting frame.

The canal bottom lining machine consists of four parts: feeding machine, spreading machine, trowel machine, and folding frame. The feeder is placed on the canal slope, the frame is connected with the spreader frame, and there are walking wheels at the bottom of the frame for traction and control of walking. Evenner, trowel and noodle collecting frame are placed in parallel at the bottom of the canal, keeping a distance between them.

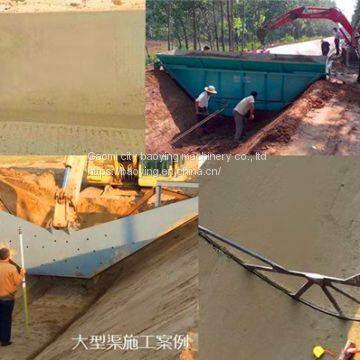

The full-automatic cast-in-place molding machine for seepage canals can cast canals formed in hundreds of meters or kilometers. According to the development of water conservancy, water conservancy canal planning is an important work in the early stage of water conservancy, so the production of high-quality cast-in-place canal machines by our factory can make a contribution and provide a help for the canal cause in various regions.

When this principle is applied to Yuanxiong U-shaped groove forming machinery, it is a phenomenon that the excess water and gas in building brick layering are compressed by high amplitude vibration, so that the structure of U-shaped channel can be equal in compactness from outside to inside, and the overflow cement slurry can also make the surface layer achieve luster effect.

Send Inquiry to This Supplier

You May Also Like

-

Disposable Slipform Machine for Baoying Water Conservancy Canal Self-propelled Slipform Machine for Drainage Canal Automatic Forming Machine for Anti-seepage CanalUS$ 8000 - 100000MOQ: 1 Set

-

Automatic Forming Machine for Baoying Water Conservancy Canal Automatic Forming Machine for Drainage Ditch Self-propelled Forming Machine for Concrete Side DitchUS$ 8000 - 100000MOQ: 1 Set

-

Automatic Forming Machine for Baoying Water Conservancy Canal Automatic Forming Machine for Drainage Ditch Self-propelled Forming Machine for Concrete Side DitchUS$ 8000 - 100000MOQ: 1 Set

-

Ditch Forming Machine Ditch Channel Slipform Machine Farmland Drainage Ditch MachineUS$ 8000 - 100000MOQ: 1 Set

-

U-shaped Concrete Canal Forming Machine Canal Slipform Machine Drainage Ditch Lining Machine for Highway ConstructionUS$ 8000 - 100000MOQ: 1 Set

-

Cast-in-place Channel Forming Machine Highway Side Ditch Channel Sliding Form Machine Self-propelled U-shaped Channel Repairing MachineUS$ 8000 - 100000MOQ: 1 Set

-

Automatic Forming Machine for Baoying Water Conservancy Canal Automatic Forming Machine for Drainage Ditch Self-propelled Forming Machine for Concrete Side DitchUS$ 8000 - 100000MOQ: 1 Set

-

Full-automatic U-shaped Channel Forming Machine Self-propelled Channel Forming Machine Cast-in-place Channel Slipform MachineUS$ 8000 - 100000MOQ: 1 Set

-

Trapezoidal Drainage Ditch Molding Machine Canal Slipform Machine Canal Molding Machine Bucket Canal Irrigation and Drainage Canal Cast-in-place Canal Molding MachineUS$ 8000 - 100000MOQ: 1 Set

-

Baoying Drainage Ditch Slipform Machine/trapezoidal Channel Forming Machine/rectangular Side Ditch Slipform MachineUS$ 8000 - 100000MOQ: 1 Set