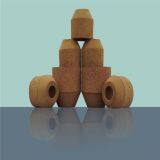

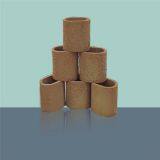

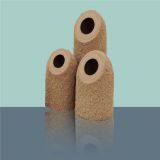

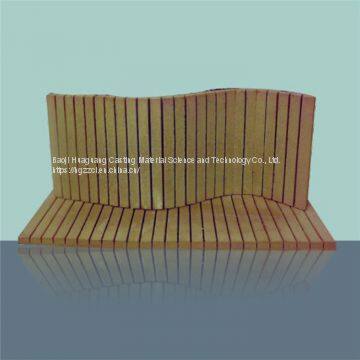

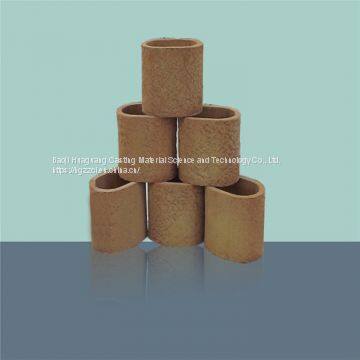

Foundry Straight Firber Composite Insulation Riser

Heating mechanism: The exothermic insulation riser head has adopted good insulation material and high efficient exothermic. There are little quenching effect, once the liquid steel was pour into the riser head, the exothermic reaction will be activated, then the riser head will heat the liquid steel with it's fever. After the reaction, the insulation material will ensure the coagulation time of the liquid steel. The best feeding efficient comes from the characters: Initial adiabatic, then fever, heat preservation for a long time in the end.

Advantages: Prolong the coagulation time2.55--2.9 multiple than the sand mold riser, the molten steel for feeding reduce 50-70%, the production ratio improved as much as 25--30%, it can reduce the contact area of the riser and the casting piece in the process of the top riser. Compared with the common sand mold riser, it can reduce 60--70% of the cutting and grinding area ,which reduce the fee of clearing and reduce the cost.

The loose shrinkage defect also can be eliminated if use exothermic insulation riser head. You can harvest stable casting pieces in the automatic molding line. It can be used for cooling the riser for its febrile. It can also reduce the pouring system ,which is good for nodular iron casting.

The features of the exothermic insulation riser head: The strength of this riser increases 50--70% than the common sand riser. There is little damage during molding, the air permeability is quite good, the thickness of the wall of the riser head is equality, the V shape centrum on the top of the closed riser can improve the adiabatic and feeding effect, also it can make the heat insulation performance and physical performance of the riser head more stable at the same time.

More information pls check our web:

Send Inquiry to This Supplier

You May Also Like

-

Investment Casting Steel Insulator FittingUS$ 1.2 - 2.5MOQ: 100 Kilograms

-

Cast Iron,Cast Steel And Stainless Steel Insulated Slag RemoverUS$ 320 - 500MOQ: 1 Metric Ton

-

Y-type Flanged and Insulating Jacket Casting Steel Globe ValveNegotiableMOQ: 1 Unit

-

Lost Wax Casting Stainless Steel 304 316 Adjustable/cushioned/rigid/U-bolts/Two Bolt/three Bolt Yoke/Riser Clamps China Manufacturer Plumbing Fitting Pipe ClampUS$ 0.3 - 2.7MOQ: 50 Pieces

-

Processing and Production of Polyurethane Polymer Insulated Transportation Floor Stick High Strength Wear-resistant Cast Steel nNegotiableMOQ: 1

-

Galvanised Plate Cast Iron Post Insulator Steel Pipe Flange and Flanged FittingsNegotiableMOQ: 1

-

1-1/4\", 2-1/2\" Steel Die Cast EMT Compression Insulated Connector, EMT Conduit And FittingsUS$ 0.1 - 2.0MOQ: 1 Piece

-

Lost Wax Casting Steel Insulator FittingUS$ 1.2 - 2.5MOQ: 100 Kilograms

-

Improve Melting Quality For Cast Iron Cast Steel And Stainless Steel Insulated Slag RemoverUS$ 320 - 500MOQ: 1 Metric Ton

-

Cast Iron Insulator CapUS$ 1.059 - 1.059MOQ: 1000 Meters