Air Blown Fiber Optic Introduction

Air Blowing cable technology is a new way to make significant improvements in traditional fiber optic systems, facilitating the rapid adoption of fiber optic networks and providing users with a flexible, secure, cost-effective cabling system.

The blowing system consists of micro-tubes (single micro-tubes and micro-tubes), micro-cables, fittings and air blowing equipment.

Air Blowing cable technology development

In 1982, BT invented the Air blown cable technology.

In 1987, the British company Berry invented the single Air blown fiber technology.

In 1988, the world's first installation of indoor blown fiber was achieved.

In 1993, the entire system was developed and officially named as a Air blown fiber system and commercialized.

In 1997, the Netherlands air blown 10pcs of ø10mm micro tubes in a ø63/50 mm mother tube. NKF Telecom, a subsidiary of the DRAKA Group, used the air blowing technology and equipment of the Swiss company Politi to realize the commercial use of the network air blowing technology for the first time. This technology covers long-haul trunk lines, metropolitan area networks and fiber-to-the-home in Europe and the United States.

In 1995, former China Ministry of Posts and Telecommunications company cooperated with Swiss company Politi and the United States Dulan Company, for the fist time introduced the world's advanced air blowing cable technology and equipment to China.

The Air Blown Application

The air blown fiber cable is composed of a combination of micro tubes (bundles), optical fibers (bundles), and blowing fiber devices.The air compressor is used as the power source for the traction fiber bundle, and the fiber bundle is quickly sent to the same micro tube bundle in the micro tube, and different types of fibers (beams) can be mixed and blown in different micro tubes.

To achieve fast installation and improved installation quality, all air-blown fiber cable are equipped with international standard prefabricated connectors on one end.

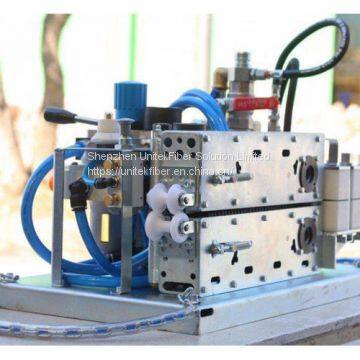

Air Blowing Fiber Optical Cable Machine

The Laying methods of Air Blowing cable compare with other Fiber Optical cable, the tension of the Air Blowing Cable during the laying process is relatively uniform and much smaller.

The Air Blowing cable laying process is simplified and fast.

The Air Blowing cable can lay a long distance in one time. It will reduce the number of joints and reduce the attenuation.

The Air blown cable can greatly reduce the number of manholes and hand holes on the pipeline.

There is less manpower used in blowing cable laying operations.

It is convenient to replace the new type of optical fiber in the future, keep leading in technology and constantly adapt to market needs.

Send Inquiry to This Supplier

You May Also Like

-

1U Jack Mounted 96fibers MPO & MTP Optical Patch PanelUS$ 100 - 200MOQ: 1 Kilometer

-

24 Ports Wall Mounted Fiber Optical Patch PanelUS$ 100 - 200MOQ: 1 Kilometer

-

ADSS Fiber Optic CableUS$ 100 - 200MOQ: 1 Kilometer

-

Aerial Fiber Optic CableUS$ 100 - 200MOQ: 1 Kilometer

-

Fiber Optic Air Dancer Costume, Adult Fiber Optic CostumeUS$ 1 - 467MOQ: 1 Piece

-

GSM900MHz RF Bast Station Fiber Optic Repeater Air Couple or BTS Couple Fiber Optic Signal Booster AmplifierUS$ 1 - 1,000MOQ: 1 Set

-

Professional Manufacture Supply Waterproof and Air Proof Fiber Optic Splice Joint BoxUS$ 12.5 - 13.5MOQ: 1 Piece

-

Air Blowing Micro Fiber Optic CableUS$ 100 - 200MOQ: 1 Kilometer

-

Air Blown Fiber Optic CableNegotiableMOQ: 1 Set

-

36 Core Air Blown Fiber Optic CableUS$ 0.1 - 5MOQ: 1 Kilometer