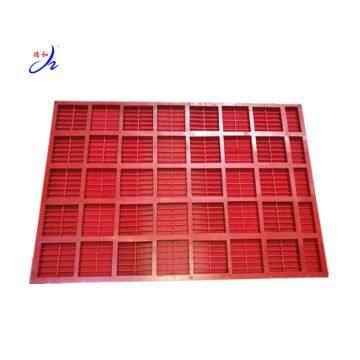

Polyurethane screens used in mining service with PU

1.Corrosion-resistant, non-flammable, non-toxic and odorless.

2.Mesh sieve unique manufacturing process design, limit size of the particles does not block the sieve.

3.Vibration absorption can be good, strong silencer, can reduce the noise, and make the matter on the screen is not easily broken in the process of vibration.

4.Due to the characteristics of the poly secondary vibration, polyurethane screen panel has since cleaning effect, so high screening efficiency.

5.Saving energy, poly proportion small, much lighter weight than the same size steel sieve, and thus reduce the load on the screening machine, saving power consumption and extend the machine life.

Contact:

Brittany Yan

TEL:+8613363824287

Anping County Xinghuo Metal Mesh Factory

Send Inquiry to This Supplier

You May Also Like

-

King Cobra Used in Solids Control Equipment With Materials SS304 or SS316US$ 60 - 70MOQ: 1 Piece

-

Composite Types SWACO MD-3/2 Shale Shaker Screen for Solids Control EqiupmentUS$ 65 - 80MOQ: 1 Piece

-

KEMTROM 33 Shale Shaker Screen on Stock With Materials SS304 or SS316US$ 55 - 70MOQ: 1 Piece

-

Steel Frame Types 1250*850 Shale Shaker Screen for Oil DrillingUS$ 55 - 70MOQ: 1 Piece

-

2000 Series Flat Shaker Screen for Oil DrillingUS$ 40 - 50MOQ: 1 Piece

-

500 Series Wave Type Shale Shaker Screen for Solids Contorl EquipmentUS$ 50 - 65MOQ: 1 Piece

-

SWACO Mongoose Composite Shale Shaker Screen for Solids Control EqiupmentUS$ 65 - 80MOQ: 1 Piece

-

King Cobra Steel Frame Shaker Screen With Material 304 or 316US$ 60 - 70MOQ: 1 Piece

-

626 Series Wave Type Shale Shaker Screen for Solids Contorl EquipmentUS$ 50 - 60MOQ: 1 Piece

-

2000 Series Wave Type Shaker Screen With Material SS304,SS316US$ 50 - 60MOQ: 1 Piece