Taisn 111 Industrial Metal Repair Epoxy Putty Casting Iron Repair Putty

Taisn 111 Epoxy Putty for repairing casting iron

Product features:

Double components, high strength metal-filled epoxy putty. Suitable for repairing and restoring of blowholes, shrinkage, flow marks and cracks in iron casting parts.

Physical Properties

Color: | Cast iron |

Specific gravity: | 1.62g/cm³ |

Mix ratio by weight: | 7:1 |

Mix ratio by volume: | 4:1 |

Working time(min): | 60min |

Compressive strength(GB/T1041): | 110.0MPa |

Tensile strength(GB/T6329): | 42.0MPa |

Shear strength(GB/T7124): | 20.0MPa |

Flexural strength(GB/T9341): | 70.0MPa |

Hardness(GB/T2411): | 82Shore D |

Cured time for machining: | 24h |

Temperature range: | -60~160℃ |

How to use:

1.Surface Cleaning:

Remove the oil and grease from the surface, also should be abrasived and polished.

2. Mixing

Two-part, please mix and forge the two parts by equal ratio. It will become gel-formulation at the low temperature, it can change into soft gel heating by the heating producer.

Notice: Do not heat with the open-fire

After 24 h room cure, it can put into use.

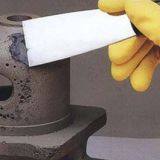

3.Coating

First, coating the surfaces with some glue, and then push and repeat coating the surface until it exhaust the air and fully fill the gap.

4.Curing

When the room temperature is lower than 10°C, and after 1-2 h room cure, use heat producer heating for 3-4 hour bewteen 80°C, the heating producer between the parts should keep a distance of 300-400mm. and the small-area fittings can be put into the oven for heating below 80°C.

(Heat Producer: infra-red lamp, electric stove, and other heating sources, not use the open-fire)

5.Post-Processing

After cured some time, it can be processed by ordinary ways, and wait for 18 hour, it can use the machine for processing.

Attention

1、When the temperature is below 15 ℃, some heating measures should be adopted; or the relevant curing time should be extended

2、When mix volume is more than 200g, the working time will be shorter

3、Above data is typical

Package:

500g/set, 16sets/carton

10kg/drum or customized

Contact Information

Send Inquiry to This Supplier

You May Also Like

-

Taisn 212K Grey Color Anti-Abrasive Ceramic Pearls Epoxy Coating for MiningUS$ 10 - 15MOQ: 100 Kilograms

-

Tiptop Type Conveyor Belt Repair Adhesive Glue, SC3000 Cold Bond CementUS$ 7 - 7.5MOQ: 500 Kilograms

-

China RTV Silicone Sealant Gasket Maker ManufacturerUS$ 0.4 - 0.45MOQ: 5000 Pieces

-

China Cheap RTV Silicone Sealant Gasket Maker SupplierUS$ 0.4 - 0.45MOQ: 5000 Pieces

-

China Cheap Modified Acrylic AB Adhesive Glue ManufacturerUS$ 0.21 - 0.25MOQ: 10000 Sets

-

China Good Quality Modified Acrylic AB Adhesive Glue SupplierUS$ 0.21 - 0.25MOQ: 10000 Sets

-

China 4 Minutes Epoxy SteelUS$ 0.65 - 0.7MOQ: 20000 Sets

-

China Rapid Steel EpoxyUS$ 0.65 - 0.7MOQ: 20000 Sets

-

Permatex Quality Anaerobic Thread Locking Adhesive ThreadlockerUS$ 0.45 - 0.5MOQ: 3000 Pieces

-

Permatex Quality Grey Color RTV Silicone Sealant Gasket Maker 85gUS$ 0.6 - 0.65MOQ: 5000 Pieces