Wheat Flour Snacks Making Machine

Wheat Flour Snacks Making Machine

Product Description

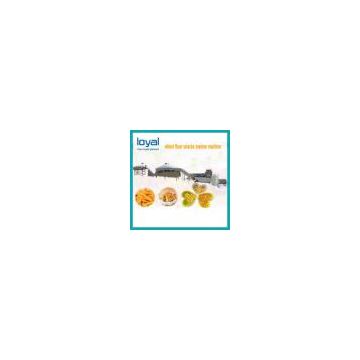

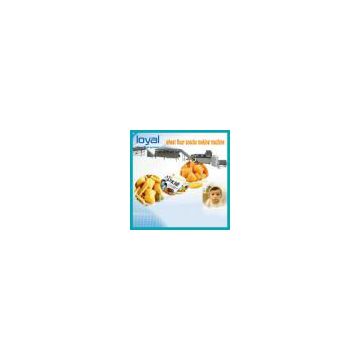

Doritos Chips Machine always use wheat flour ,corn flour as raw material through twin screw extruder extruding , then through forming machine to roll cut different shapes of products ,such as bugles,doritos, flat bread snacks, sala sticks, rice chips and also Fish shape,Moon shape, Bugle shape,Duck shape etc. Snacks.

The Machine is foodstuff equipment researched and developed on the basis of international advanced technology. The performance and quality have reached the highest international level of the same line. From feeding materials, extruding and inflating, roasting, spraying to finished products are done once time with automation. We fill the gap of the first-class food produced with extruded and inflated technology.

Main Features:

1) Stable performance: adopting imported frequency or electromagnetic controlling

system, high automation and smooth operation

2) Permanent working life: with special material and technology, the screw and nut

involved can work continuously for 1 year under conditions of high wear and pressure

Machine advantage and feature:

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials; Segmental screw is applied to more kinds of materials and production. At the same time, it is easy to change and reduce the replacement cost.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system which could adjust the speed with more powerful drive, stable running, and low consumption.

3. Automatic lubrication system in gear box, it could reduce power consumption and prolong the life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Hanging mould and knife steat can increase the speed of replacing mould and knife.

Contact Us

Shandong Alvin Import and Export Co., Ltd.specialized in microwave drying and sterilizing machine, microwave heating equipment, microwave dryer, microwave sterilization equipment, microwave drying equipment, multi-grain microwave curing equipment, seasoning microwave drying sterilization machine,melon microwave dryer, etc. . Microwave equipment has been widely used in ceramics, food, building materials, chemicals, pharmaceuticals, rubber, paper products, refractory materials, agricultural and sideline products, leather, textiles and other industries. Wheat flour snacks making machine

Send Inquiry to This Supplier

You May Also Like

-

Automatic Fried Wheat Flour Puff Snacks Food Making MachineUS$ 10,000 - 30,000MOQ: 1 Set

-

Stainless Steel Cereal Bar Making Machine , Snacks Making Machine / EquipmentUS$ 10,000 - 30,000MOQ: 1 Set

-

Full Automatic Puffed Corn Snack Making Machine Jam Center Core Filling Snacks ProductionUS$ 10,000 - 30,000MOQ: 1 Set

-

High Quality Automatic Puffed Snacks Making MachineUS$ 10,000 - 30,000MOQ: 1 Set

-

Fully Automatic Pet Food Production Line For Dog Food, Fish FeedUS$ 10,000 - 30,000MOQ: 1 Set

-

Automatic Fully Production Line Dry Pet Dog Food Pellet Making ExtruderUS$ 10,000 - 30,000MOQ: 1 Set

-

One Year Warranty Pet Food Production Line/extruder Pet Food/dry Dog Food Making Machine With Factory PriceUS$ 10,000 - 30,000MOQ: 1 Set

-

2019 Hot Sales Automatic Dog Cat Fish Shrimp Bird Pet Snack Food Extruder Plant Production Line Equipment MachineUS$ 10,000 - 30,000MOQ: 1 Set

-

Continuous Automatic Pet Food Production LineUS$ 10,000 - 30,000MOQ: 1 Set

-

Continuous Automatic Pet Food Production Line For Dog / Cat / FishUS$ 10,000 - 30,000MOQ: 1 Set