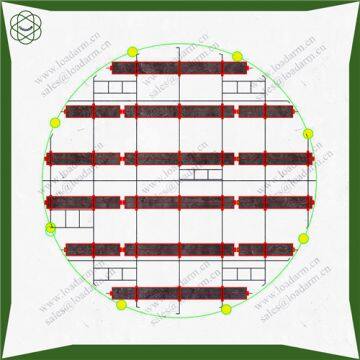

Assembling Aluminum Internal Floating Roof Deck Disk for Storage Tank

The aluminum internal floating roof can be manually assembled quickly. It has a strong hexagon structure and effective seal. The aluminum internal floating roof can be applicable for various sizes of storage tanks. The floating roof itself does not pollute oil or chemicals. It can reduce the volatilization of medium, preventing air pollution. With low cost, short construction time, corrosion resistance, taking us little space and having a long service life etc, it is an ideal internal floating roof.

Standard accessories of internal floating roof: vent valve, gauge hatch, liquid level device, floating plate, manhole, anti-rotation device, anti static device and steel tape level gauge.

Special accessories of internal floating roof: Sampler, diffuser, vents etc.

PRODUCT CHARACTERISTICS | |

1 | With special hexagon web structure, the frame of the internal floating roof has good strength and stability. The structure itself can have a damping effect, could reduce and dissolve the shock wave quickly. |

2 | Having many small sizes pontoons, which increase the operation feasibility. The pontoons are separated from the frame, and uniform distributed, which can prevent the floating roof from inclining and getting stuck after one or two pontoons are punctured. It increases the stability of the internal floating roof. |

3 | Energy saving and consumption reduction is 98%. The space of oil&gas in the floating roof is small, which can reduce the evaporation of product and reduce consumption. |

4 | High utilization ratio of storage tank. The thickness of the internal floating roof structure is only 320mm, thus increasing the storage space and utilization rate of storage tank. |

5 | Safe, simple, quick installation, low maintenance cost. The installation of floating roof is bolt connection or riveting, with no welding. It’s also suitable for remould tank. The spare parts have good interchangeability and commonality, can be replaced separately. It is convenient in installation and maintenance. |

6 | High corrosion resistance and long service life. The main part of floating roof is made of good material with good anti-corrosion performance and long service life. The seal material have good electric conduction and abrasion resistant performance, good elasticity and not easy to crack. |

Send Inquiry to This Supplier

You May Also Like

-

Aluminium Internal Floater for Gasoline Storage TankUS$ 1 - 78000MOQ: 1 Set

-

Storage Tanks Internal Floating CoversUS$ 1 - 78000MOQ: 1 Set

-

Chemical Storage Tank Internal Floating RoofUS$ 1 - 78000MOQ: 1 Set

-

Liquid Loading Arm AL1401US$ 1200 - 3500MOQ: 1 Set

-

Factory Price Liquid Loading ArmUS$ 1200 - 3500MOQ: 1 Set

-

Manufacturer of Folding Stair Step LadderUS$ 1200 - 3500MOQ: 1 Set

-

Marine Loading Arms AM63US$ 1200 - 3500MOQ: 1 Set

-

Aluminum or Stainless Steel Internal Floating RoofUS$ 1 - 78000MOQ: 1 Set

-

Heat Tracing Top Loading Unloading Arm ManufacturerUS$ 1200 - 3500MOQ: 1 Set

-

Gasoline Bottom Loading ArmUS$ 1200 - 3500MOQ: 1 Set