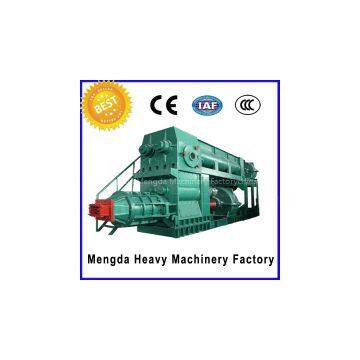

Mengda Brand High Performance Clay Brick Making Machine

Introduction:

JZK series brick making machine (vacuum extruder) is uesd to produce all kinds of hollow brick, red brick, split brick with the material of coal gangue, shale, fly ash, slag or clay and so on.

The clay brick making machine is the most important equipment in the brick production line and our brick making machine is suitable for producing all kinds of cell bricks with materials of clay, coal gangue, shale, fly ash and so on.

Our clay brick making machine has floowing Advantages:

lid and durable properties, reasonable structure and reliable performance.

2.Large capacity and smooth operation.

3.Good sealing, high vacuum degree and extrusion pressure.

4.Low power consumption and high efficiency.

5.Reasonable design,easy installation,upper and lower motor could use T-square or straight line type

installation.

Technical features of our clay brick making machine:

1.We take advantage of aging,quenching and tempering technology to handle the main body of extruder,such as mixer shaft, the main shaft of trowel.

2.The reducer gear has hard tooth surface and spray with wear-resistance material to increase the working years.

3.The vacuum chamber is designed to funnel-shape,which is able to empty the air more quickly than the square chamber.

4.The remear adopts high chrome alloy trowel to insure long service life.

5.Clutch adopts screw press technology,which improves the service life of our brick machine.

6.The mixing paddles is separated from the mixing shaft so that it can be easily maintenance.

7.The spindle is processed quenching and pressure testing to enhance stiffness and toughness.

Service we supply:

We supply full set of turnkey project for brick making machine production line, including the complete line design, engineering management, civil engineering of kiln and drying chamber, the foundation building, supplying, installation of all the equipments, the supplying and installation of compressed air, water and power system and etc. After we complete the whole project, we will pass the production lien to customer for using directly.

Technical Parameter

| Model | Production | Power | Dimension |

| Jzk 30-2.0 | 4000 - 6000 | 45 - 55 | 3450x1220x1320 |

| Jzk 35-2.0 | 6000 - 8000 | 55 - 75 | 3750x1340x1550 |

| Jzk 40-3.0 | 8000 - 10000 | 90 - 110 | 4750x1500x1650 |

| Jzk 45-3.0 | 10000 -13000 | 110 - 132 | 4960x1680x1750 |

| Jzk 50-3.5 | 13000 -18000 | 55 + 132 | 5350x1800x2100 |

| Jzk 55-4.0 | 14000 -20000 | 75 + 180 | 8360x2800x3590 |

Email :mengdafanny@outlook.com

Mobile:8615838225098

Skype:mengdafanny

Http:///

Send Inquiry to This Supplier

You May Also Like

-

Paving Stone Making Machine Cement Hollow Brick Making Machine 2-hole Hollow Brick Making MachineUS$ 1050MOQ: 1 Combo

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece