Conveyor Belt Repair

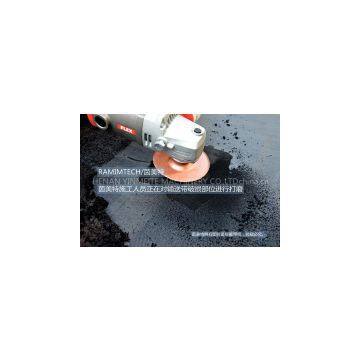

1.Conveyor belt damaged parts grinding

RAMIMTECH builders grind the damaged parts with angle grinder. (above photo)

First, mark the damaged parts, then grind the damaged parts with L1202 angle grinder and tungsten carbon disc until the damaged surface has a certain radian and non convex.

2. Coat the damaged parts with cold vulcanizing glue.

After grinding conveyor belt, cleaning the damaged parts is necessary, deeply clean the damaged parts with cleaning solvent SK353. ( above photo)

Ramimtech builders mix the cold vulcanizing glue SK313 with hardener UT-R40, their mixing ratio is 100:4.( above photo)

Ramimtech builders coat the semi-cured repair strip with cold vulcanizing glue. ( above photo)

Clean the damaged parts, then coat it with cold vulcanizing glue SK313 with hardener UT-R40 mixture. After totally dry, then coat the mixture again, wait they have little stickness but not attached to finger back. However, coat the repair strip once only.

3. Repair strip bonding

After applying repair strip to conveyor belt, construction builders is now use roller stitcher. (above photo)

Conveyor belt damaged parts apply RAMIMTECH cold vulcanizing system to finish repair.(above photo)

Bonding repair patches to damaged parts. During the bonding procedure avoid air entering, then use roller stitcher to press repair strip to exhaust air.

Send Inquiry to This Supplier

You May Also Like

-

Mold Release Agent for Bakery Industry CompliantUS$ 1 - 4MOQ: 200 Kilograms

-

Cyanuric Acid 25kgNegotiableMOQ: 1 Ton

-

Honeycomb Zeolite 4a Lithium Adsorbent Desiccant Xintao Dehydration 3a Powder Molecular SieveNegotiableMOQ: 1

-

SUNRA007 Electric Passenger TricycleNegotiableMOQ: 1

-

The Machine AccessoriesNegotiableMOQ: 1

-

Disc Type Zinc Dust ChargerNegotiableMOQ: 1

-

Cosmetics Packaging BagNegotiableMOQ: 1 Metric Ton

-

Modified Starch for Paper IndustrialUS$ 630 - 650MOQ: 5 Tons

-

NA Cmc Powder Food GradeUS$ 550 - 3,690MOQ: 5 Tons

-

Diapers Baler Hydraulic Pressing Baling MachineUS$ 3,200 - 3,250MOQ: 1 Set