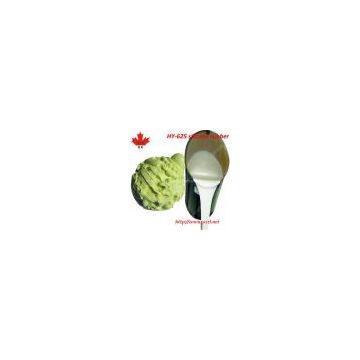

HY- E625 Addition Molding Silicone rubber

Applications:

HY- E625# addition molding silicone could be mainly used for making concrete stones, precision molds, PU molds, for life casting, fabric finishing, shoe soles making, seal for electronic components and solar circuit board, trademark decoration. etc.

OPERRATING INSTRUCTION:

1. Clean your products and brush a layer of release agent (detergent or soap water) on the surface of your product.

Note: The model should not have been used to make molds for tin cured silicone rubber before. Otherwise, the addition silicone will not get cured. (Use a new model to test it)

2. Enclose the product (the original model) with four plastic plates or wooden plates.

3. Mixing part A and part B with 1:1 mixing ratio and stir evenly. And get the mixture for vacuum-pumping. (If there is no vacuumizer, you can just pour the mixture slowly from the corner so that less bubbles caused)

4. Pour the mixture into the model frame.

After about 2-4 hours, when the silicone cured, get out the original model, and there you get a finished addition cured silicone mold .

Send Inquiry to This Supplier

You May Also Like

-

Cyanuric Acid 25kgNegotiableMOQ: 1 Ton

-

Honeycomb Zeolite 4a Lithium Adsorbent Desiccant Xintao Dehydration 3a Powder Molecular SieveNegotiableMOQ: 1

-

SUNRA007 Electric Passenger TricycleNegotiableMOQ: 1

-

The Machine AccessoriesNegotiableMOQ: 1

-

Disc Type Zinc Dust ChargerNegotiableMOQ: 1

-

Cosmetics Packaging BagNegotiableMOQ: 1 Metric Ton

-

Modified Starch for Paper IndustrialUS$ 630 - 650MOQ: 5 Tons

-

NA Cmc Powder Food GradeUS$ 550 - 3,690MOQ: 5 Tons

-

Diapers Baler Hydraulic Pressing Baling MachineUS$ 3,200 - 3,250MOQ: 1 Set

-

Leather Wall Panel for Background and Ceiling PanelUS$ 3 - 6MOQ: 200 Pieces