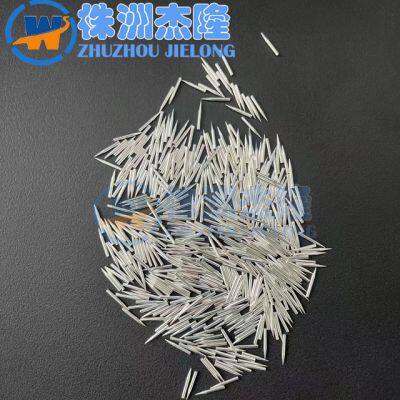

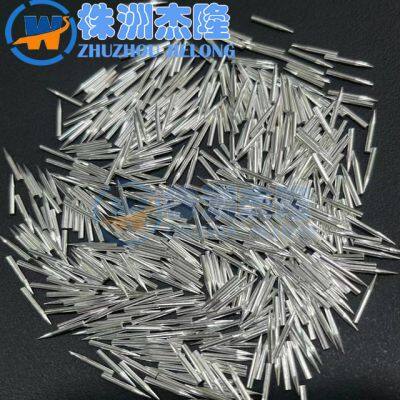

Tungsten Needle for Dust Collector or Air Purifier

Tungsten needles

Product performance

High precision and efficiency: We specialized in production of many other tungsten products with decades of research and production experience. Our company is well-equipped, which can be produce by customized to customer' requirement and create customized solutions for you.

Tungsten needles are widely used in electronics, welding, medical equipment, EDM and other fields due to their high melting point, high hardness and high corrosion resistance.

Due to its unique atomic-level sharpness, tungsten needles are also widely used in microscopy, nanotechnology prepare microscope samples, atomic tip probes, electron beam etching, and other fields etc.

Tungsten needles can also be used for precision surgery because their cutting accuracy is extremely high and they cause little tissue damage. It is require higher sharpness and tolerance.

Our tungsten needles have Wear resistance, high temperature resistance, corrosion resistance, so it is will be reduce repairs time, it is improve working time

Full size: we can offer Pointed Tungsten Needle, Tungsten Probe, Tungsten Discharge Needles , We have almost all the sizes in stock and can provide you with immediate delivery. In the aspect of intensive processing of tip treating, bending forming, slotting, open pore and thread with advanced technology and experiences.

the Extensive Applications of Tungsten Needles in Industry

Tungsten needles, composed of refractory alloys, are ultra-sharp electrodes widely used across various industrial sectors. Their advantages, such as excellent conductivity and high-temperature resistance, make them an indispensable functional material in modern industry. Electrical Discharge Machining (EDM) and CNC Machining Tungsten needles are extensively used in electrical discharge machining (EDM) and computer numerical control (CNC) machining. They can precisely process various metal materials such as carbon steel, stainless steel, silicon copper, copper, bronze, and titanium. The high hardness and wear resistance of tungsten needles enable them to withstand high temperatures and pressures, ensuring machining accuracy and efficiency. Welding Applications Tungsten needles play a significant role in the welding field, especially in tungsten inert gas (TIG) welding. During welding, an arc is created between the tungsten electrode and the workpiece, and filler metal is fed into the weld pool formed by the heat of the arc. Due to their high melting point and temperature resistance, tungsten electrodes prevent melting and burn-off, making them ideal for welding thin sheets (up to 4mm) such as pipes and tube-to-tube plate connections. Instrument Probes Sharp-tipped tungsten needles are primarily used as instrument probes. For example, in digital four-probe testers, which measure the resistivity and sheet resistance (thin layer resistance) of semiconductor materials. The fine tips of tungsten needles ensure precise contact with the material being tested, obtaining accurate measurement data and improving the precision and reliability of testing. Discharge Machining Tungsten needles are also used in discharge machining processes. During discharge machining, both the workpiece and the electrode (tungsten needle) are immersed in a dielectric fluid, and high-voltage pulses create sparks between the workpiece and electrode, causing localized melting and evaporation of the workpiece surface to achieve machining. The high melting point and temperature resistance of tungsten needles ensure their stability and durability in discharge machining. Air Purification In air purification systems, tungsten needles serve as discharge electrodes. By applying high voltage to the tungsten needle, corona discharge is generated, which charges airborne particles, allowing them to be collected and thus purifying the air. The high-temperature resistance and corrosion resistance of tungsten needles ensure their stability and longevity during the discharge process. Military Applications Tungsten needles have significant applications in the military field. Historically, tungsten was used in weaponry during the cold weapon era. For instance, Chinese archaeologists have detected tungsten in excavated "treasured swords." During World War I, German arms engineers highly valued tungsten-containing gun barrels. Data from that time showed that Russian and French light machine guns could fire around 6,000 rounds before wearing out, whereas German light machine guns, utilizing tungsten, could fire up to 15,000 rounds, more than doubling the performance. The high hardness and wear resistance of tungsten make it widely used in military equipment. In conclusion, tungsten needles, with their exceptional physical and chemical properties, have extensive applications across various industrial fields. They are an indispensable functional material in modern industry. With technological advancements, the applications of tungsten needles in industry are expected to become even more widespread and profound.

Why used tungsten produce?

Hard and Durable: Tungsten is second only to diamond in hardness, making tungsten needles extremely hard and long-lasting

High temperature resistance: The melting point of tungsten is as high as 3422°C and can be used in high temperature environments without deformation.

Chemically Stable: Tungsten has excellent corrosion resistance and will not be attacked by most chemicals

Good conductivity: Tungsten is an excellent conductive material and is often used in electrodes and probes

Main Features

Tungsten products are produced with the use of 100% raw material. We used tungsten rods, it have low thermal expansion and good thermal conductivity, and are sufficiently resistant to electrical resistance. In particular, they have a very high melting point, strong physical properties, professional sharpening technology, smooth surface, and the best concentrated discharge effect at the tip of the product.

Why Choose Us?

The price is cost-effective

We are a tungsten needles of manufactuer, the price is more compete

Quality guaranteed

We have decades of professional technology and experience, stable quality and fast delivery time.

How to choose the appropriate tungsten needle specification?

Common shapes of tungsten needles include round, flat and triangle. Choose the appropriate specifications and shape according to your welding needs.

How to choose the appropriate tungsten needle diameter?

Generally, the greater the current, the larger the diameter of the tungsten needle required

Send Inquiry to This Supplier

You May Also Like

-

High Purity 99.95% Tungsten Crucible and TubeNegotiableMOQ: 1 Piece

-

Tungsten HeaterNegotiableMOQ: 1 Piece

-

High Quality Pure Tungsten Sheet, Purity 99.95%NegotiableMOQ: 1 Piece

-

Tungsten Boats for Vacuum BoatingNegotiableMOQ: 1 Piece

-

High Purity 99.95% Pure Tungsten PlatesNegotiableMOQ: 1 Piece

-

Black or White Tungsten WiresNegotiableMOQ: 1 Piece

-

High Quality Tungsten BarsNegotiableMOQ: 1 Piece

-

Supply Green Pure Tungsten Electrodes for TIG WeldingNegotiableMOQ: 1 Piece

-

W-Ce WC20 Gray Cerium/ceriated Tungsten ElectrodesNegotiableMOQ: 1 Piece

-

W-Th Red Polished Electrode Thoriated Tungsten Electrodes for Tig WeldingNegotiableMOQ: 1 Piece