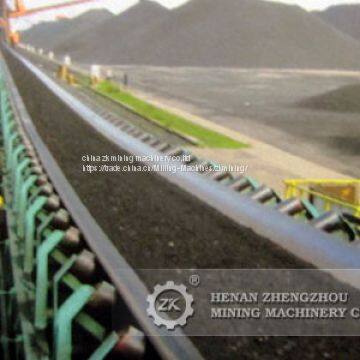

TD75 fixed type belt conveyor is used to convey bulk material or packed product, it can work single or several unit or work together with other conveyors form horizontal conveying system or inclined system. Its working temperature is between -25℃~40℃, it requires conveying material should not exceed 60℃, heat-resistance belt can convey material below 120 ℃。If material temperature higher than this, belt conveyor is not suitable. It should use oil resistance, or acid and bases proof rubber belt or plastic belt when it convey grease material or material has property of acid, bases etc.

Application :

Metallurgy, mining, coal, chemical engineering industries.

Our products advantages:

1. Wide range of conveying material, it can convey wet, dry, powdery or lump material or packed product.

2.Big conveying capacity and long conveying distance.

3.It even can realize multipoint load material and discharge.

4.Stable running, small noise.

5. Simple structure, reliable working, easy operation, easy installation and maintenance.

Structures:

1) Driving device of conveyor has open type and closed type. Open type: it is consist of motor, high speed coupling, brake, gearbox, low speed coupling. pin roller. The unit mount together on a steel base (motor power within 10kW), or mount on concrete base separately.( motor power more than 115kW). Closed driving device is electric drum, motor and gearbox system are mounted inside of drum. Compared to open driving device. its features are compact, safe operation, small land area, light, low cost. TD75 various specification drum to match its requirement.

2) At material feeding area, design impact roller to reduce impact from material to belt.

3) In order to avoid off-tracking, install one set groove aligning roller every 10 set on load section, install one set horizontal aligning roller every 6-10 set on on-load branch.

4) The tension gear has different type, which is suitable for to different condition.

Send Inquiry to This Supplier

You May Also Like

-

Cement Plant Bag Filter for SaleUS$ 16000 - 89000MOQ: 1 Set

-

Rotary Coal Dryer ManufacturersUS$ 16000 - 89000MOQ: 1 Set

-

High Efficiency Low Price Cement Vibrator FeederUS$ 13000 - 30000MOQ: 1 Set

-

Stone Crushing Plant Price for Sale With Full ServiceUS$ 10000 - 86000MOQ: 1 Set

-

Aggregates 200-250TPH Quartz Stone Crushing PlantUS$ 1000 - 63000MOQ: 1 Set

-

Cone Crusher Machine, Stone Crushers Price in ChinaUS$ 13000 - 69000MOQ: 1 Set

-

Energy-savin Energy-saving Ball Mill for Mining Grinding Equipmentg Ball Mill for Mining Grinding EquipmentUS$ 13000 - 85000MOQ: 1 Set

-

Competitive Small Stone Jaw Crusher PriceUS$ 15000 - 36000MOQ: 1 Set

-

Sand Making Plant Circular Vibrating ScreenUS$ 13000 - 63000MOQ: 1 Set

-

Sand Vibrating Screen, Crushing and Screening PlantUS$ 300 - 8000MOQ: 1 Set