The Maintenance Method for Coal Slurry Dryer

1.With reach coal dryer manufacture experience, Yufeng will offer you professional after-sale service. Expecially maintenance is important factor during machine running.

2.Bearing is a part of equipment which take full weight of dryer, the choice of tube have a great influence on service life and rotation rate. So it would be better if we can sure it's clear and with good sealing performance.

3.Gear is also important device, it's the key of transmission, we should do preventive maintenance regularly, remove the rust and add lube. This method also applies to the transmission.

4.Finally, it's cleaning dryer's inner structure regularly. Because the wet material with high moisture easily stick upon the wall of drum, if we don't clearn it regularly, it will be clogging in the dryer. So cleaning method is running dryer without wet materials, thus those sticky material will be dried and out off drum wall, as the same time, rapping on a barrel wall of dryer in the rules.

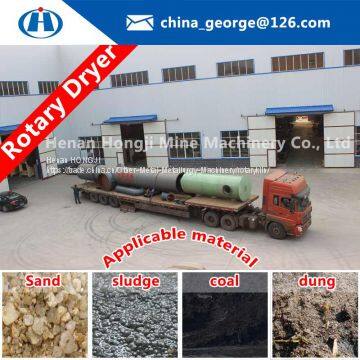

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Factory Price Good Quality Dry Process Cement Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Factory Price Good Quality Aluminium Hydroxide Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Factory Price Good Quality Wet Process Cement Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Factory Price Good Quality Soda Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Grinding Mill Stone Sale to DenmarkJPY 1 - 1MOQ: 1 Short Ton

-

Agitator Attriator Ball Mill IndiaJPY 1 - 1MOQ: 1 Short Ton

-

Ball Mill Cement Plant RussiaJPY 1 - 1MOQ: 1 Short Ton

-

Ball Mill 100 kg Capacity PhotographsJPY 1 - 1MOQ: 1 Short Ton

-

Ceramic Ball Mill Supplier in IndiaJPY 1 - 1MOQ: 1 Short Ton

-

Small Ultrafine Mill Price ChinaJPY 1 - 1MOQ: 1 Short Ton