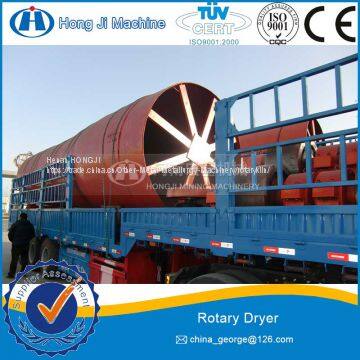

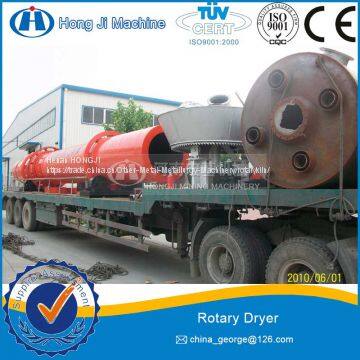

1.Picture of rotary dryer:

Rotary dryer is a type of industrial dryer employed to reduce or minimize the liquid moisture content of the material, it is handled

by bringing it into direct contact with a heated gas.

Materials can be dried by rotary dryer:

1.Aggregates

2.Agricultural grains&by-products

3.Animal waste

4.Animal feed

5.Ceramics

6.Clay

7.Fertilizer

8.Gypsum

9.Iron ore concentrate

10.Limestone

11.Metal chips&shavings

12.Mining ores& concentrate

13.Municipal waste

14.Municipal sludge

15.Organic & inorganic chemical

16.Paper sludge

17.Potash

18.Sand

19.Steel mill waste

2.Description of rotary dryer:

Rotary dryer is widely used for drying materials in the industries of cement, mine, construction, chemical, food, compound fertilizer, etc. Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier's feeding end can be indicated by the thermometer to control the inner drier temperature ( generally 250-350°C).

3.Rotary DryerWorking Principle

Rotary Dryer adopts direct flow type of heating with heat source from firing unit. The material to be dried is pushed back immediately by spiral board when enters the shell from feeding tank and feeding chute. Because the drier is installed in slope, material flows to the back end under gravity and rotation force, meanwhile, it is lifted by board repeatedly and thrown down accordingly, which make the material form even curtain, and exchange heat sufficiently with inner the heat flow. In the end, water in the material is dried by repeatedly scattering.

4.structure of drying equipment of rotary dryer:

Rotary dryer is formed by rotary body, lifting blade, driving device, supporting device and sealing ring.

Rotary dryer is mainly composed of shell, back and forth supporting wheel, feeding and discharging unit and gear cap. The accessories which are not in the the scope of this machine include firebox, feeding and discharging equipment, dust catcher, etc.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Professional Drying Sand, Slag, Coal, Wood, Bagasse, Sawdust Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Professional Silica Sand Rotary Dryer From HenanEUR 1 - 1MOQ: 1 Ton

-

Cow Manure Bio-fertilizer Pellet Rotary Dryer PriceEUR 1 - 1MOQ: 1 Ton

-

Energy Saving Wood Chips Rotary Dryer ManufacturerEUR 1 - 1MOQ: 1 Ton

-

Fertilizer Rotary Dryer for SaleEUR 1 - 1MOQ: 1 Ton

-

Professional Wood Chips Rotary Dryer for Sale With Good PriceEUR 1 - 1MOQ: 1 Ton

-

Professional Rotary Dryer, Roller Dryer, Sand Dryer PriceEUR 1 - 1MOQ: 1 Ton

-

Lignite/Mineral Slag/quartz Ore/iron Powder Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Dryer Balls/industrial Tumble Dryer/rotary Dryer PriceEUR 1 - 1MOQ: 1 Ton

-

Widely Used Silica Sand Rotary Dryer,wooden Rotary Dryer for SaleEUR 1 - 1MOQ: 1 Ton