China TOP Class welding machine hdpe geomembrane

Description |

High-density polyethylene (HDPE), commonly used as a geomembrane and is similar to the material used in black polyethylene pipes. It has a broad chemical resistance and excellent UV resistance, but has a lack of flexibility and can develop brittle stress cracking at low stresses if not properly formulated.

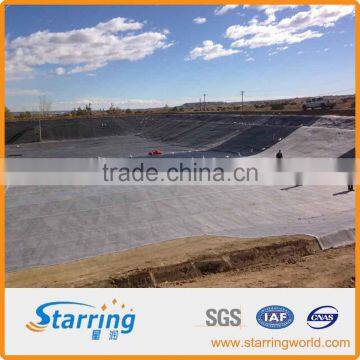

Since HDPE is a very stiff material, it cannot be prefabricated into panels. Instead it is delivered to the site in rolls, usually up to 8m wide and all the seaming is done on-site. The HDPE liner is rolled out and laid across the channel with overlapping pieces to enable weld joining.

Application

We have network of approved installers who can arrange on-site welding

and installation services for landfill, stormwater and effluent ponds.

Geomembranes are manufactured using high density polyethylene (HDPE). HDPEis produced in various thicknesses and with smooth or embossed

structured surfaces. The geomembranes provide a complete seal against even the most toxic substances. It is typically used in sealing applications for landfill base seals as well as caps, in environmental sealing applications for the protection of groundwater from contamination and in water conveyance structures, canals or ponds.

Features

• Versatile sealing applications possible

• Excellent chemical resistance due to selected raw materials

• Extreme high elongation during uni-axial and multiaxial deformation

• High stress cracking resistance

• Very high UV-resistance

• Direction independent shear stress transfer with structured surfaces

• High interface friction angles with embossed structured surfaces

• Slope dependent structured surfaces available for project specific designs

• Complete quality control from the resin to the final product

• High Melt Flow Index allows an excellent welding performance

• Smooth edges with removable plastic tape for clean welding surface and overlap lines

• ISO 9001: 2000 certified

Installation |

Method of installation

The HDPE was supplied 8m wide rolls of approximately 200m in length. To allow easier installation, reduce labour requirements on site, and reduce the amount of joining in wet and dirty site conditions, some workshop prefabrication was undertaken. Approximately four water authority personnel and three from the supplier were required to install the material, which included welding sections together.

The 200m section was laid and welded in approximately two days. The liner was anchored in trenches along the channel bank and the end treatment utilised geosynthetic clay lining (GCL).

Technical Parameters (GRI-GM13)

Properties | Test method | GM SH075 | GM SH100 | GM SH125 | GM SH150 | GM SH200 | GM SH250 | GM SH300 |

Thickness | D5199 | 0.75mm | 1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

Density | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile properties 1. Yield strength 2. Breaks strength 3. Yield elongation 4. Break elongation |

D6693 Type IV |

11KN/m 20KN/m 12% 700% |

15KN/m 27KN/m 12% 700% |

18KN/m 33KN/m 12% 700% |

22KN/m 40KN/m 12% 700% |

29KN/m 53KN/m 12% 700% |

37KN/m 67KN/m 12% 700% |

44 KN/m 80 KN/m 12% 700%

|

Tear resistance | D1004 | 93N | 152N | 156N | 187N | 249N | 311N | 374N |

Puncture resistance | D4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N |

Stress crack resistance | D5397(App.) | 300hr | 300hr | 300hr | 300hr | 300hr | 300hr | 300hr |

Carbon black content | D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

Oxidative induction time (OIT) | D3895 | 100 min | 100min | 100min | 100 min | 100min | 100min | 100min |

Send Inquiry to This Supplier

You May Also Like

-

High Adhesive, Water-proof, Anti Corrosion, Weather-resistant Asphalt Adhesive Glue Patch Cover for ConstructionNegotiableMOQ: 100 Rolls

-

Non-curable Rubber Modified Asphalt Coating for WaterproofingUS$ 1.5 - 6MOQ: 500 Kilograms

-

Low Cost Waterproof Material ManufactureUS$ 1,000 - 50,000MOQ: 1 Set

-

Cheap Price Diesel Engine M11 3080760 Cylinder LinerUS$ 27 - 29MOQ: 6 Pieces

-

2000 Cups Membrane Film Different Color Sealing Cup Sealing MachineUS$ 88.2 - 112MOQ: 12 Rolls

-

Adjustable Aluminum Alloy Rope Suspended Platform ZLP 800 For Refurbishing / PaintingNegotiableMOQ: 1 Meter

-

PTFE Architectural Membrane MaterialNegotiableMOQ: 1

-

Sell SBS Waterproof Sheet MaterialsNegotiableMOQ: 1 Meter

-

Special Compound BaseUS$ 0.12 - 0.25MOQ: 7000 Square Meters

-

Concrete Embedment Strip for Waterproof Geomembrane LinersNegotiableMOQ: 1 Piece