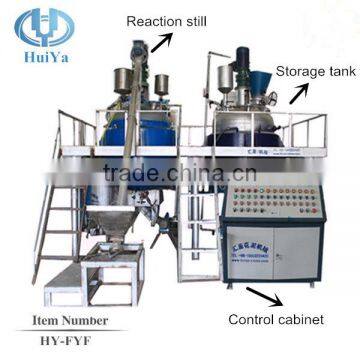

1.Synthetic Resin Equipment( Reaction still)

The inside wall of reactor is 304 stainless steel. Automatic control cabinet is used to accurately control the temperature and input materials, which can enjoy stable product quality and reduce production time and labor.

2.Two component Floral foaming machine

Microcomputer PLC control. TIAN electrical components exclusively imported to achieve the goal for automatic, accurate and reliable control, it can be imputed with more than 500 working positiondata; pressure, temperature and rotation rate digital tracking and automatic control; equipped with abnomity of fault alarm devices. Imported converter(PLC)can control eight different product ratio.

3.Foaming machine

Using automatic electrical heating temperature control system to make floral foam heat evenly and maintain the temperature. And it makes floral foam shaped constantly with uniform and enjoys little waste.

4.Vertical cutting machine

Simple operation. It's equppied with suction machine, which greatly redeuce the floral foam powder pollution and makes working environment healthy.

5.CNC horizontal cutting machine

Computer control, simple operation equipped with suction machine.which greatly redeuce the floral foam powder pollution and makes working environment healthy.

6.PLC horizontal pushing printing machine

This machine is used to cut the slice into bricks, then the floral foam bricks go into PH processing system. The process is automatically controlled by PLC, which greatly improves the prduction efficiency and quality.

1.Can i visit your factory to see the producing line?

YES, welcome you to visit our factory, we will show you the features of our floral foam producing equipment and our company.

2.What about the configuration of the production line?

We have different configuration according to your factory scale.

1) one unit of reaction still + one unit of storage tank + foaming machine +cutting machine + related accessories. (Standard configuration)

2) one unit of reaction still without storage tank + foaming machine +cutting machine + related accessories.

3) two unit of reaction stills and/or one or two unit of storage tank + foaming machine +cutting machine + related accessories.

3.What about the required area for producing floral foam for install the whole standard configuration production line?

The whole set of production line need 600 square meters area at least, a certain area of storage room is necessary according to your producing capacity.

4.What about your lead time?

Normally 40days is enough for one set of standard configuration production line.

5.What about the packing and shipping?

Sea worthy package, for one standard configuration, 2*40’HQ is needed.

6.Do you provide a technical train service if we buy your production line?

Yes, before the equipment factory delivery, you can send your technical staff come over to our factory to learn operation method until he think it is ok for operation.

7.What about the quality guarantee?

12months. if any problem, we will try our best to help you to resolve it ASAP forever.

Send Inquiry to This Supplier

You May Also Like

-

Biological Products and Preparation VesselNegotiableMOQ: 1 Set

-

Professional Factory Essential Oil Soap Making MachineNegotiableMOQ: 1

-

Magnetic Stirring KettleUS$ 1100 - 1800MOQ: 1 Piece

-

85C~ 120C High Temperature Start-up Test And Runing Test Equipment for Electricity Car Drive MotorUS$ 7,000 - 90,000MOQ: 1 Set

-

ELECTROMAGNETIC SIEVE SHAKERUS$ 500 - 1,500MOQ: 1 Set

-

PE Machinery Water Tanks , Plastic Tank, Fuel TankUS$ 20 - 90MOQ: 1

-

Active Lime Rotary Kiln Burning Plant for SaleUS$ 1,000,000 - 2,000,000MOQ: 1 Set

-

Upender Machine for Organic Fertilzier Fermentation (CE)US$ 1,500 - 60,000MOQ: 1 Set

-

Microwave Supercritical Extraction EquipmentUS$ 2,900 - 5,000MOQ: 1 Set

-

Hand Held Portable Fiber Laser Marking Machine For Meta Products Processing 20wUS$ 7410 - 8780MOQ: 1 Set