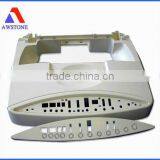

1. plastic injection mold parts description

Name | plastic injection part mould |

Main cavity material | 2738,2343,DIN-1,S130, 2344, NAK80,S316 P20 |

Mould base standard | LKM, HASCO |

Mould cavity quantities | multi |

Mould life | 500K—1000K |

Injection material | PA, PC, ABS, PET, POM, PA66+GF, PVC, Nylon |

Design software | PROE, CAD, Solidworks, UG |

package | Wooden case package or as client’s |

Payment | T/T, L/C, western union |

Price term | FOB Shenzhen, China |

2. injection mold manufacturing factory:

| Awstone introduction | Awstone are specialized mold manufacturer. We have 17 years of manufacturing experience. We have own management system. We can provide customer high quality with low cost. |

| communication with clients | We have special mold technical project engineer for every project,. And we will take charge of following things: (1)Follow up every process of the whole project, to make sure mould production is 100% according to client. (2)Make sure to reply every customer question promptly. (3)Keep in touch with customer closely, inform customer of the problem in time when any problem occurs, and provide solution for customer reference. (4)Provide project progress chat and pictures to customer every week. |

| mould analysis | We do detail analysis for every new project, to make sure the project will be finished according to customer quality requirement in time. And our mould analysts early predict the possible problem and prepare precautions accordingly, so mould production time and cost can be saved for customer. |

| Professional mould | We have own R&D team, design team and analysis team. We can R&D own product, design drawings for customers and analysis project value. |

| Service | We can provide plastic & metal parts and assembly ,providing a broad range of service from design ,molding, stamping , rapid prototype , precision maching,assembly, and final package. |

| Certification | ISO/TS16949 |

1. Manufacturing welcome: plastic injection mould,plastic products,hardware parts, 3D printing prototypes..

2. Sample order

3. We will reply you for your inquiry in 24 hours.

vide our suggestion for improve product design

5. after sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Medical equipment, optical, electronic device, cable TV components, plumbing, home appliance, electrical equipment, security device, military hardware, packaging equipment, automotive, transportation equipment etc

Send Inquiry to This Supplier

You May Also Like

-

Agriculture Using Plastic Shape Moulds Heart, Star, Square, Flower Shape Cucumber and Fruit MouldNegotiableMOQ: 500 Pieces

-

GYC Small 300-600kg/h Toilet Soap Making Machine From OilNegotiableMOQ: 1

-

OEM Customized Molded Enclosure Injection Plastic Molding For ElectronicsNegotiableMOQ: 1

-

Vanity TopNegotiableMOQ: 1

-

Brand New Waterproof Pvc Flooring With Great PriceUS$ 80 - 117MOQ: 1 Piece

-

Mould For ScrubberNegotiableMOQ: 1

-

Fully Automatic Cotton Swab Making Machine With Packing And Drying | Cotton Bud Maker Machine Wooden Cotton Swab Making MachineUS$ 23,500 - 23,500MOQ: 1 Set

-

Plastic Motor Part Mould, Laptop Plastic Parts Mould Such as Side Body Motorcycle, Fairying Covers for Motorcycle!US$ 0.1 - 2MOQ: 5000 Pieces

-

6.35mm Adjustable M2-M10 Carbon Steel Body Die Holder Wrench Set for Power ToolsUS$ 1 - 30MOQ: 640 Pieces

-

2016 Hot Selling Concrete Plastic Paving Mould for Interlock Tile MakingUS$ 1 - 5MOQ: 500 Pieces