The spent grain dryer is widely used to process varioushigh wet materials into organic fertilizer. It adopts one-step molding technology. It mainly recycles stock faeces and agricultural waste as raw materials to not only take income for the enterprise, but also serve company to take responsibility for the environment.

2.scope of application

Agricultural waste: husks, straw of grain, bean pulp,etc.

Residue of bio-gas.

Stock faeces: mixture of poultry litter and animal waste.

Industrial waste: wine lees, vinegar residue, sugar scum, etc.

Household garbage: food waste, the roots and leaves of vegetables, etc.

Sludge: the sludge of the river, paper mill, etc.

3.Working process

The spent Grain drying production line is a complete set of equipment from raw materials collection to the organic fertilizer packing.

Fermenting process: the first process of the production line is organic materials fermentation. In the initial production preparation, the compost will be first conveyed to a compost turner to turn and mix to accelerate the fermentation reaction rate.

Crushing process: during this procedure, a crusher will be used to grind the compost lumps to prepare for the later granulating process, but if the compost is fine enough, this step can be left out.

Batching process: if several kinds of materials in the formula need to be added, for improving process efficiency and the accuracy of composition ratio, we can adopt the automatic batching system, which is composed of a plurality of belt scales; if we plan to make pure organic fertilizer, this step can be also left out.)

Granulating process: Disc granulator is widely used in this process to make fertilizer particles. As the key procedure of the whole production line, we will help to select the most appropriate granulating machine to meet customers specific demands.

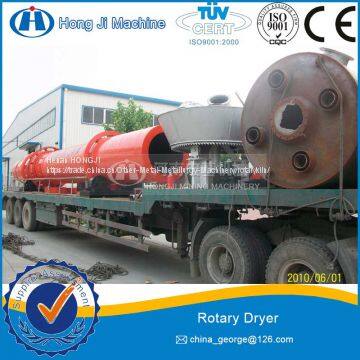

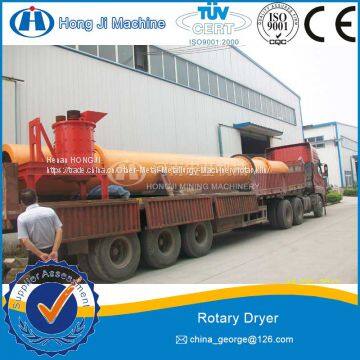

Drying process: for re-molding and better storage, the moisture of the fertilizer particles should be no more than 14%, therefore, we need to dry the fertilizer to the required moisture when it is over 14%. And rotary drum dryer is usually applied to dry the wet materials.

Cooling process: in order to make fertilizer particles stronger, rotary drum cooler will be adopted to meet this requirement.

Screening process: rotary drum screening machine will be applied to separate the moderate granules from the oversized or tiny particles that need to crush and granulate secondly.

Coating process: rotary drum coating machine will be applied to coat the fertilizer particles and prevent particles adhesion.

Packaging process: in the last process, fertilizer packaging machine is used to package bags automatically and quantitatively.

Dedusting system: all the dust generated by the crusher, granulator, dryer, cooler, and screener will be collected and centralized processed by the dedusting system.

Auxiliary facilities, such as belt conveyor and bucket elevator, are also needed to connect each process to complete the whole organic fertilizer production line.

4.Specification and Technical parameters

The whole line is centralized controlled and highly automatic, which is convenient to operated.

Compact process layout, reliable performance, easy maintenance.

The production line uses animal faeces and other kinds of waste as its raw materials, which not only converts useless materials into valuable commodities, but also protects our environment.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Rotary Sludge DryerEUR 1 - 1MOQ: 1 Ton

-

Totary Tube Coal DryerEUR 1 - 1MOQ: 1 Ton

-

Harga Rotary Drum DryerEUR 1 - 1MOQ: 1 Ton

-

Jual Pinion for Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Coal Briquetting DryerEUR 1 - 1MOQ: 1 Ton

-

Sludge Drying in WaterEUR 1 - 1MOQ: 1 Ton

-

Cost of Drying SandEUR 1 - 1MOQ: 1 Ton

-

Sand DryerEUR 1 - 1MOQ: 1 Ton

-

Rotary Dryer AdalahEUR 1 - 1MOQ: 1 Ton

-

Kapasitas Rotary DryerEUR 1 - 1MOQ: 1 Ton