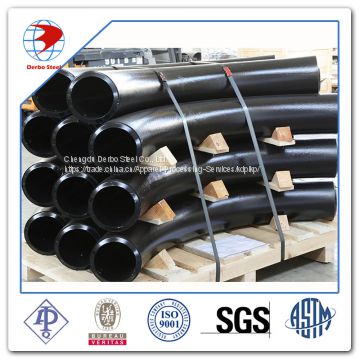

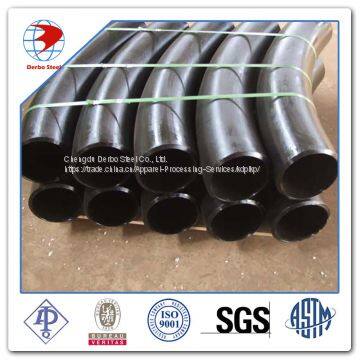

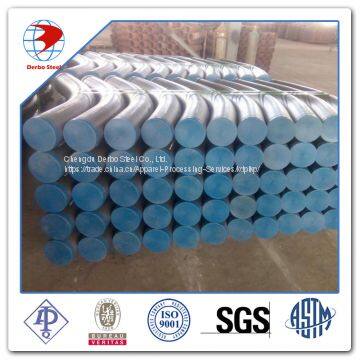

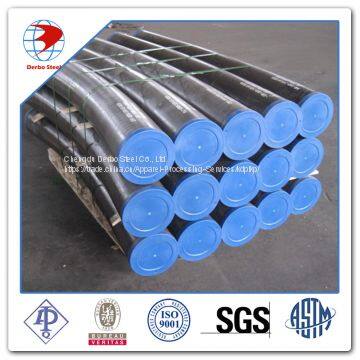

Carbon Steel Seamless API 5L X65 5D Butt Welding Bend

Our Carbon Steel Seamless API 5L X65 5D Butt Welding Bend applied to oil and gas industry with premium API 5L X65 carbon steel. We have succeed to cooperated with SHELL,LUKOIL and other famous oil &gas companies with small order,best quality,reasonable price

5D Butt Welding Bend,Butt Welding Bend,API 5L X65 Bend

BENDS SPECIFICATION REQUIREMENTS

GENERAL DESCRIPTION

Outside Diameter: 1/2" to 100"

Thickness: SCH20, SCH30, SCH40, STD, SCH80, SCH100. SCH120, SCH160. XXS

Design Life: 30 Years

Pipeline Design Code: ASME B16.9, ASME B16.49/ MSS-SP75

Service Fluid: Full Well Stream, Offshore Shallow Water Application, Subject to Potential Late Souring andEventual Bacteria induced Corrosion.

Third Party Inspection: Required (Upon agreement with COMPANY and Mechanical tests to be witnessed)

MOTHER PIPE REQUIREMENTS:

Material: Carbon Steel

Grade: API 5L - Gr.B/X42/X46/X52/X60/X70 etc.(PSL1 & PSL2),ISO 3183- L245/L290/L320/L360/L415/L485(PSL1),ISO 3183- L245N/L245R/L290Q/L360Q/L415Q/L485Q(PSL2)

Specification: API 5L: ISO 3183: 2007

BEND REQUIREMENTS

Specification:API 5L: ISO 3183: 2007

Charpy Impact Test:Required, per API 5L: ISO 3183: 2007 MSS SP75

Hardness Test:Required, per API 5L: ISO 3183: 2007 MSS SP75

Dimensional Tolerance: +/-1 degree

External Surface Treatment: 3-Layers Polyethylene / Fusion Bonded Epoxy (FBE)

Number of Qualification Bends: Per section API 5L: ISO 3183

Marking: Per API 5L: ISO 3183

Our Advantages

1. Professional Sales Team With More Than 10 Years Experience In Steel Industry.

2. Technical Engineer From Oil Company and Third Party Inspection Company.

3. One-Stop Service for steel industry, Especially for pipeline project application.

4. Rich Cooperation Experience With SHELL,Lukoil,Samsung Etc.

5. Competitive price,Fast Delivery Time,Excellent Service.

Quality Control

Quality control is the basic but most important point for qualification of the steel pipes/tubes&fittings. We carry out in-production supervision and after-production inspection for our products. We ensure that the products are produced,tested,and inspected strictly according to standard specification under supervision of our QA engineer during production. After production inspection is carried out by worldwide famous third party inspection company like BV,SGS,Intertek Etc.

Send Inquiry to This Supplier

You May Also Like

-

SA 335 GR. P91 Alloy Steel Smls Pipe Plain EndsNegotiableMOQ: 1 Bag

-

Seamless Stainless Steel Pipe ASTM A312 Grade TP321NegotiableMOQ: 1 Bag

-

Sch 80 Seamless cs Pipe API 5L X60 Psl2 BE B36.10mNegotiableMOQ: 1 Bag

-

ASTM A53 Gr.b Steel Pipe With FBE Coated AWWAC213.NegotiableMOQ: 1 Bag

-

ASTM A572 Carbon Steel PlateNegotiableMOQ: 1 Bag

-

ASTM A671 CC60 Seamless Low Temperature Steel PipeNegotiableMOQ: 1 Bag

-

SCH160 Super Duplex UNS S32750 Stainless Steel PipesNegotiableMOQ: 1 Bag

-

ASTM A519 4130 Alloy Steel Gas Cylinder TubeNegotiableMOQ: 1 Bag

-

SA 192 Seamless Boiler Carbon Steel TubeNegotiableMOQ: 1 Bag

-

API 5DP G 105 NC38 EU R2 Drill PipeNegotiableMOQ: 1 Bag