Carbon Steel Boiler Tube ASTM A210 A1

1.Boiler Pipe Technical Parameters

Out diameter: 21.3mm-609.6mm

Thickness: SCH30 STD 40 80 160 XXS

Length: SRL; DRL; 5.8M; 11.8M, Fixed Length as per client`s requirements.

Steel Standard: ASTM A213

Steel Material: T5

Surface: Bare, Oiled, Anti-Corrosion Coating (3LPE 3LPP FBE Etc.);

Package: Plain/Bevel End With End Caps. Waterproof Packing, Bare Packing, In bundle, Nest Packing, Standard Export Packing

Inspection: SGS; BV.

Certificate: ISO9001; 2000

Date of Delivery: After received deposit 15-60 Days According to the Quantity

Payment: T/T; 100% L/C at sight; Western Union; D/A; D/P; O/A

Port of Shipment: Xingang Tianjin; Shanghai Port; Guangdong port; Ningbo Port; Qingdao port.

| CHEMICAL COMPOSITION (CAST ANALYSIS) IN% | |||||||

| Steel grade | C | Si | Mn | P max | S max | Cr max | Mo max |

| T5 | ≦0.15 | ≦0.50 | 0.30~0.60 | 0.025 | 0.025 | 4.00~6.00 | 0.45~0.65 |

| T11 | 0.05~0.15 | 0.50~1.00 | 0.30~0.60 | 0.025 | 0.025 | 1.00~1.50 | 0.44~0.65 |

| T12 | 0.05~0.15 | ≦0.50 | 0.30~0.61 | 0.025 | 0.025 | 0.80~1.25 | 0.44~0.65 |

| MECHANICAL PROPERTIES | |||||||

| Steel grade | Yield strength Min (Mpa) | Tensile strength Min(Mpa) | Elongation A Min(%) | Hardness Max | |||

| T5 | 415 | 205 | 30 | 85HRB (170HB) | |||

| T11 | 415 | 205 | 85HRB (170HB) | ||||

| T12 | 415 | 220 | 85HRB (170HB) | ||||

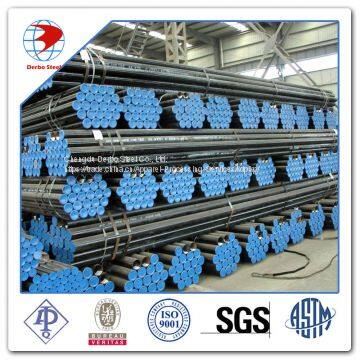

2.Boiler Pipe Showcase

3.Boiler Pipe Facility

4.Boiler Pipe Inspection Equipment

5.Boiler Pipe Packing and Transportation

Our Advantages

1. Professional Sales Team With More Than 10 Years Experience In Steel Industry.

2. Technical Engineer From Oil Company and Third Party Inspection Company.

3. One-Stop Service for steel industry, Especially for pipeline project application.

4. Rich Cooperation Experience With SHELL,Lukoil,Samsung Etc.

5. Competitive price,Fast Delivery Time,Excellent Service.

Quality Control

Quality control is the basic but most important point for qualification of the steel pipes/tubes&fittings. We carry out in-production supervision and after-production inspection for our products. We ensure that the products are produced,tested,and inspected strictly according to standard specification under supervision of our QA engineer during production. After production inspection is carried out by worldwide famous third party inspection company like BV,SGS,Intertek Etc.

Send Inquiry to This Supplier

You May Also Like

-

A269 316L Seamless Stainless Steel Tube 16mmNegotiableMOQ: 1 Bag

-

DIN1629 ST52 Cold Drawn SMLS Steel PipeNegotiableMOQ: 1 Bag

-

EN10217 P235 TR1 ERW Coated Line PipeNegotiableMOQ: 1 Bag

-

G105 NC 38 API 5D/API 5DP Drill PipeNegotiableMOQ: 1 Bag

-

DN25 SCH80 ASTM A335 P22 Seamless Steel TubeNegotiableMOQ: 1 Bag

-

High Temperature A335 P11 SMLS Alloy Steel PipeNegotiableMOQ: 1 Bag

-

RF B16.5 Blind CS Flange A105NegotiableMOQ: 1 Bag

-

3in 1500Lb SS316 Graphite Filled Spiral Wound GasketNegotiableMOQ: 1 Bag

-

A312 TP316L ANTI H2S Seamless Stainless Steel PipeNegotiableMOQ: 1 Bag

-

API 5CT J55 BTC 9 5/8inch R3 CasingNegotiableMOQ: 1 Bag