Energy Saving symon GF series cone crusher price

1.Product overview

Energy Saving symon GF series cone crusher price is a new type crusher Which mainly used to crush medium and low hardness brittlematerials, for example coal, soft coal, coal gangue, lignite, sinter, shale, coke limestone and etc.

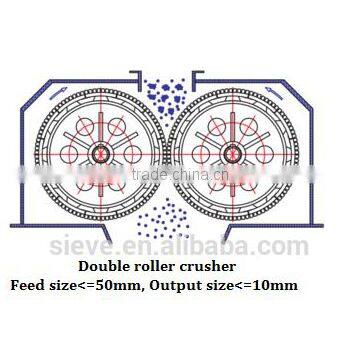

2.Working Principle:

Energy Saving symon GF series cone crusher price composed by rollers which rotate toward each other , material directly falls into for the size in accordance with two teeth roll gap, exceed the gap’s material are crushed by rollers of splitting, breaking, and striking then falls to meet the granularity’s requirement. Relative roller differential operation can clear up the slot residual materials, all of this avoidance the material’s repeated crushing, without gluing and plugging.

3.Energy Saving symon GF series cone crusher price data

(Max feeding size<=50mm, Output size<=10mm)

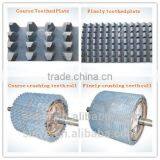

4.Product details:

Energy Saving symon GF series cone crusher price have a German technology and special design of tooth profile, high wear-resistant alloy steel, modular combination tooth plate, tooth board wear-resisting, ensure uniform granularity.

5.Energy Saving symon GF series cone crusher price adopts double

protection of electrical and mechanical, electrical control cabinet is equipped with PLC programmable controller with chain safeguard function, which can realize local control and central control room manual / automatic control, so which is the ideal crusher for heating and power supply.

6.Energy Saving symon GF series cone crusher price's Features

High yield and no gluing plugging

Small repeated crushing and uniform grain size

Low investment cost

Simple structure and convenience maintenance

Environmental protection and energy saving

Provided material uniformly and long service life

Modularization & Fast dismounting structure

7.Certificates:

8.Delivery and shipping:

9.Customer production sites:

10.Customer Visit:

11.Frequent Asked Question

1>.What is your products material?

Our product’s frame with Q235A material, teeth plate with high wear resistant alloy steel.

2>.How long the teeth plate’s replacement cycle? How long does it will be take to change one piece of teeth plate?

Teeth plate’s replacement cycle decided by the crushing material, normally one year. It’s will be take 4-5 minutes to change one piece of teeth plate.

3>.How about your products’ security performance?

Our product with four protective measures to ensure machine’s running when unbroken objects came in crushing cavity suddenly. More details, please feel free to contact us.

4>.Products warranty?

The products warranty is one year.

Thanks a lot for your interesting, we are looking forward your inquiry!

Send Inquiry to This Supplier

You May Also Like

-

Multi-cylinder Hydraulic Cone Crusher, Jaw Crusher Trituradora Crusher Plant for Mining IndustryNegotiableMOQ: 1 Set

-

Bimetal Overlay Wear Plate for Crusher Main Frame LinersUS$ 100 - 100MOQ: 1 Piece

-

Car Bodies Shredder Waste Car Logger Car Shell Compactor Car Body Baler Metal Baling MachineNegotiableMOQ: 1 Set

-

Electric Start Mobile Crusher Factory Outlet 18KW 1003086 for Sale Max.20t/h 10 Woking Days After Received The DepositNegotiableMOQ: 1

-

Rock Crusher Machine Price/Mini Hammer Mill Crusher For Coal Heavy DutyUS$ 560 - 8,600MOQ: 1 Set

-

PebblesNegotiableMOQ: 1 Kilogram

-

Precision Mechanical ComponentsNegotiableMOQ: 1 Kilogram

-

Lateral Parts And OtherNegotiableMOQ: 1 Kilogram

-

Chute FeederNegotiableMOQ: 1 Kilogram

-

Roll Crusher Used in Mining, Smelting, Building Material, Highway, RailwayUS$ 3,000 - 10,000MOQ: 1 Set