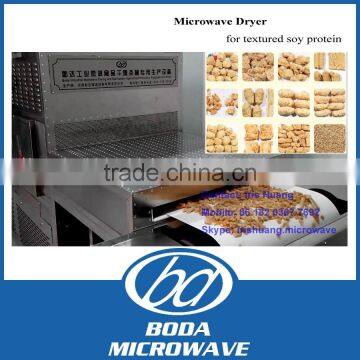

Industrial Microwave Textured Meats Drying Machine/ Microwave Textured Soy Protein Dryer

Industrial microwave textured soy protein drying machine/ microwave textured meats dryer

Model number | BDMD- F-P-30 |

Description | BODA Industrial microwave textured meats drying machine/ microwave textured soy protein dryer |

| Microwave frequency (MHz) | 2450±50 |

| Input voltage | 380V, 50Hz |

| Microwave power(KW) | 30(KW) |

Chamber material | Stainless steel |

| Chamber color | Silver-white |

| Conveyor belt | PP or PTFE belt |

| Dehydrator dimension(L*W*H)(mm) | 8.0x1.1x1.7 |

| Weight (KG) | 2500 |

| Microwave leakage limit(mW/cm2) | 1 mW/cm2 |

| Relative humidity(℃) | ≤85% |

| Ambient temperature(℃) | Normal temperature |

| Environment requirement | No excessive corrosive gas, no inflammable, explosive gas |

| Microwave dryer Model | Microwave frequency (MHz) | Microwave power | Microwave leakage | Dryer dimension (m) | Installation area (m) |

| BDMD-F-P-20 | 2450±50 | 20kw | 1mW/cm2 | 7.0x1.1x1.7 | 9x3.5x2.5 |

| BDMD-F-P-30 | 2450±50 | 30kw | 1mW/cm2 | 8.0x1.1x1.7 | 10x3.5x2.5 |

| BDMD-F-P-40 | 2450±50 | 40kw | 1mW/cm2 | 9.0x1.1x1.7 | 11x3.5x2.5 |

| BDMD-F-P-50 | 2450±50 | 50kw | 1mW/cm2 | 10.0x1.1x1.7 | 12x3.5x2.5 |

| BDMD-F-P-60 | 2450±50 | 60kw | 1mW/cm2 | 11.0x1.1x1.7 | 13x3.5x2.5 |

| BDMD-F-P-70 | 2450±50 | 70kw | 1mW/cm2 | 12.0x1.1x1.7 | 14x3.5x2.5 |

| BDMD-F-P-80 | 2450±50 | 80kw | 1mW/cm2 | 13.0x1.1x1.7 | 15x3.5x2.5 |

| BDMD-F-P-100 | 2450±50 | 100kw | 1mW/cm2 | 16.0x1.1x1.7 | 18x3.5x2.5 |

| BDMD-F-P-120 | 2450±50 | 120kw | 1mW/cm2 | 18.0x1.1x1.7 | 20x3.5x2.5 |

| BDMD-F-P-150 | 2450±50 | 150kw | 1mW/cm2 | 21.0x1.1x1.7 | 23x3.5x2.5 |

| BDMD-F-P-200 | 2450±50 | 200kw | 1mW/cm2 | 27.0x1.1x1.7 | 29x3.5x2.5 |

Usage:

The microwave dryer is used to dry textured soybean protein, textured meats, textured fishes in low temperature to preserve the original nutrition of them.

Advantage:

Microwave textured soybean protein drying machine has a number of quantitative and qualitative advantages over conventional drying machines so that it becomes more and more popular. One main advantage is the place where the heat is generated, namely the product itself. Because of this, the effect of small heat conductivities or heat transfer coefficients does not play such an important role. Therefore, larger pieces of foods can be heated in microwave dryer in a shorter time and with a more even temperature distribution. The another main advantages is the short drying time, low drying temperature of microwave dryer. Textured protein can be dried in about 2 minutes, which greatly preserves the nutrition and color of them.

- Energy saving 30%-60%

- Drying speed 50% quicker

- Reduced CO2 emissions

- Increased drying efficiency and yield

- Drying temperature adjustable

- Suitable for drying textured soy protein

Wooden packing for each set of microwave dryer if needed.

Soft packing is supplied.

BODA provides a full range of services and technical support for industrial microwave systems. The services include custom installations, preventive equipment maintenance, equipment upgrades and modifications and microwave system repair.

1. What is Microwave?

Microwaves are a form of electromagnetic energy with frequencies between 300 MHz and 300 GHz, generated by magnetrons under the combined force of an electric and a magnetic field perpendicular to each other.

2. What is the advantage of Microwave dehydrator compared to Conventional dehydrator?

Conventional dehydrator is a surface dehydration method, which is not only slow, but also non-uniform with the surfaces, edges and corners being much dehydrated than the inside of the material. The imperfect dehydration will cause product rejections, waste energy and extend process time.

Microwave fruit dehydrator and vegetable dehydrator is a direct method of dehydration. Energy is transferred through the material electro-magnetically, not as a thermal heat flux. Therefore, the rate of dehydration is not limited, the uniformity of heat distribution is greatly improved and dehydration time is reduced.

3. How about safety?

Using scientific structure and patented suppression system, BODA industrial microwave dehydrator poses no threat of electromagnetic radiation to the health and safety of equipment operators.

4.What about maintenance?

In addition to downtime for cleaning and inspection, conventional dehydrators and heat exchangers need periodic servicing with an expensive inventory of parts and a highly trained labor force. For microwave dehydrator, the only part that requires maintenance is the magnetron. In the event of a malfunction or misuse through incorrect operation, this can easily be replaced in less than thirty minutes. Generally, BODA recommends that the magnetron of industrial microwave dehydrator be replaced annually or after 8,000 hours of operation, whichever is sooner.

Contact:

You are here: Home >> Conti Dryer >> Microwave textured soy protein dryer

Send Inquiry to This Supplier

You May Also Like

-

Coffee Bean Sorting Machine Grain Gravity Separator Machine Caraway Seed Density SeparatorNegotiableMOQ: 1 Set

-

Semi-Auto Brewing Equipment for Microbrewery With 1 Year WarrantyNegotiableMOQ: 1 Set

-

Supply OEM/ODM Bean Sprout MachineNegotiableMOQ: 1 Piece

-

Heavy-Duty 4m High Basketball Court Fence With Anti-Climb DesignNegotiableMOQ: 1 Acre

-

2019 Shanghai Genyond Small Scale Commercial Tofu Production LineNegotiableMOQ: 1

-

Peanut Cutting Machine Almond Strip Cutting Machine Fast Cutting SpeedNegotiableMOQ: 1 Set

-

Factory Price Bean Bud Seedling Machine/Bean Sprout Growing Machine For SaleUS$ 1,500 - 7,999MOQ: 1 Set

-

Large Output Sprouts Cleaning Machine Vibration ShellerUS$ 1 - 2,500MOQ: 1 Set

-

Professional Manufacturer of Soybean Milk Process MachineUS$ 1,500 - 3,000MOQ: 1 Set

-

Green Bean Sprout Making Machine/machinery/makerNegotiableMOQ: 1 Set