Biomass Wood Briquette Machine

biomass wood briquette machine

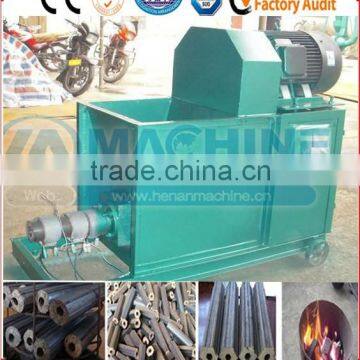

Introduction of wood/biomass briquette extruder machine

Wood/biomass briquette extruder machine equipment to crops and waste and residue, branches, wood, sawdust, coconut shells, such as biomass as raw material after crushing, rods, drying, carbonization processing technology, such as making charcoal used as fuel production barbecue with carbon, activated carbon fuel, charcoal, sawdust carbon fuel, etc.

suitable for:

sawdust, wood shavings, bamboo shavings, bark, branches, walnut, chestnut shell, cotton stalk, ZhiMaGan, corn stover, sunflower stalk, big haulm, rice husk, bagasse, corn cob and other raw material crushing (under 6 mm in diameter, such as rice husk, sawdust without crushing) through mechanical extrusion after four, six arrises edges or square perforated molding fuel.

Detailed instructions:

Wood/biomass briquette extruder machine production line design is reasonable, mature technology, simple operation, high product yield, extrusion dense uniform density, screw propeller precision casting, the use of special wear-resistant material life is longer than the traditional propeller; Molding box adopts special formula precision casting alloy material, cost is reduced greatly, and save manpower.

Working Principle of Wood briquettes extruder machine

wood/biomass briquette extruder machine production process: raw material crushing (depending on the size of raw material) - dry (depending on the size of water) - making great carbonized - molding - product put in storage

Detailed parameters of all the models for your checking:

Model | MF-50 | MF-80 |

Output (kg/h) |

180-210 |

340-360kg |

Motor Power (kw) |

15 kw |

22kw |

Electric heater (kw) |

2kw×3pcs |

2kw×3pcs |

Weight(kg) |

700 kg |

1100kg |

Overall dimension(mm) | 1780*750*1290 | 1960*880*1620 |

Size of finished products |

Diameter: |

Diameter: |

features of wood/biomass briquette extruder machine:

1.This product design is reasonable, manufacturing quality and reliable, has a simple structure, convenient operation, small volume, covers an area of less, the characteristics of the province, save electricity.

2. The design of automatic control electric heating device, can randomly adjust the dry humidity of materials, guarantee the stability of the material forming, improve work efficiency.

3. This product is the main parts adopt wear-resisting material through special processing, can suppress the production continuously, and durable.

4. Suitable for all kinds of biomass raw material and forming, and low energy consumption, high production efficiency.

5. Change the three bearing for four of the old machine heart, increase the stability and durability of the machine.

6. Change the old oil lubrication for oil-immersed lubrication, as long as no shortage of oil, can be used for many years.

7. Increase the pitch increasing feed rate, thus greatly increased the production.

8. Improve the forming tube structure, reduced the mechanical and the friction of the raw materials, increase the density of the mandrel.

The auxiliary machine:

wood/biomass briquette extruder production line equipment include: crusher, dryer, stick machine, coking furnace.

Transfer machine

Crushing machine

rotary screen

dry machine

material distributer:

finally product

Payment,Packing and Delivery

Payment :30% TT in advance, 70%6TT balance pay off before delivery.

Packing: The machine and wear parts will protected by plywooden box or as customers’ will.

Delivery time: For one set, the delivery time is 7-10 days, for 1-5 sets 20-25 days, above 5 sets usually negotiate.

Shipping company: MSK/MSC/APL/EMC/WANHAL/KLINE and We will remind you before boat arrive and offer you all the customs clearance documents on time.

Company promises:

1. For customers free training technical personnel according to the purchase contract,

2.our company can send engineers to guide free installation and debugging

3. the company perennial supply machine parts

4. Collect customer feedback, timely formulate implementation plan, resolve customer problems. 5. Our company guarantees machine according to the national standard.

Contact Information

Thanks for your interest in our machines and please contact us freely if you have any questions ot requirements by the following contact information. Your visit of our factory to test the machines you like will be warmly welcomed. Hope to have have the honor to cooperate with you in the bright future.

Send Inquiry to This Supplier

You May Also Like

-

Good Price Biomass Wood Pellet Machine Rice Huck Pellet Making Machine Peanut Shell Pellet MachineUS$ 690 - 3880MOQ: 1 Set

-

China Factory Wholesale 500KW Industrial Electric Silent Power Diesel GeneratorNegotiableMOQ: 1 Set

-

Humic Acid Fertilizer Pellet Machine(CE)US$ 880 - 99,000MOQ: 1 Set

-

Pellet Briquetting Machine / Rice Husk Pellet Mill PriceUS$ 25,000 - 25,000MOQ: 1 Set

-

Wood Pellet Mill Machine for Wood Dust Pellet PressUS$ 1,000 - 10,000MOQ: 1 Set

-

Energy Saving Straw Coal Briquette MachineUS$ 2,000 - 3,000MOQ: 1 Set

-

Diesel Flat Die Small Pellet MillUS$ 500 - 1,000MOQ: 1 Set

-

Industrial Complete Flat Die Wood Pellet Production LineUS$ 20,000 - 25,000MOQ: 1 Set

-

Factory Directly Wood Pellet Press, Wood Pellet Press Machine, Gemco Supply Wood Pellet MillUS$ 3,000 - 4,000MOQ: 1 Set

-

Hot Sale and Best Quality Wood Briquette Machine Screw PressNegotiableMOQ: 1 Set