Petro Chemical Process Pumps

Petro Chemical Process Pumps

1. What is KDY Petro Chemical Process Pumps ?

KDY Petro Chemical Process Pumps is developed with internationally advanced technologies. It is designed for long-distance transportation of liquids without solids and corrosion, especially of crude petroleum, petrol-oils and other high pressure applications.

2.What are the features of KDY Multistage Oil Pump ?

1. Quality guaranteed. It has API610 (8th Edition) standard design and certified by ISO9001.

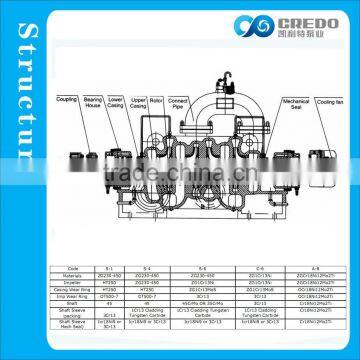

2. Easy operating. With both suction inlet and discharge outlet located in pump casing, it has no need to disturb the piping and motor when maintaining and serving the internal parts, even no need to open the pump cover when replacing mechanical seals and bearings.

3. Safe. Twin volute design and opposed symmetric impeller arrangement combined to obtain perfect radial and axial balances under all operation conditions. Double suction impellers plus inducers may also be utilized for reduction of cavitations.

4. Flexible. Pump shaft, with computer optimized design, keyed with the impellers symmetrically arranged on the shaft, rotor assembly strictly checked with computer program to ensure controlled radial flexibility and dynamic balance,.

5. Advanced leak-proof technology. Advanced hydraulic model engenders compact construction with spacious internal passageway efficient for crude oil of high viscosity. The high-strength bolts, computer optimized designed, connect upper and lower casings together and ensure a leak-less operation at super pressure conditions.

6. Heat resisting. Shaft sealed with high pressure mechanical seals that are forcibly cooled and rinsed with solution treated through vortex separations, which makes it applicable for pumping of high temperature liquids and crude oil, besides the mechanical seals are located at the low pressure area far away from the center where the high pressure zone lies.

7. Bearing and coupling systems are designed for heavy duty and high speed operation. The SKF centripetal thrust bearing plus self-lubricating or forcibly lubricated slide bearing shall balance the remnant axial force. Air and water cooling are available for slide bearings, elastic bolts coupling and membranes plus intermediate coupling selectable.

8. Pump temperature, vibration and leakage are monitored and alarmed both locally and remotely. Automatically control of the pump could be realized through connection with customer’s auto systems.

3. performance range of Petro Chemical Process Pumps Flow Range: 25~8000m3/h Head Range:60 ~ 1600m Fluid Temp.:Up to 260℃ Viscosity:Up to 800 mm2/s |

| 4.Description of Credo KDY Petro Chemical Process Pumps |

e.g. DZY650-100A X 6

DZY — Multi-stage split case petrol pump 650 — Capacity (m3/hr) 100 — Single stage head (m) 6 — No. of stages

Variations: A — impeller first cutting |

Polywood Case; as per customer requirement// 45-60days after payment

Send Inquiry to This Supplier

You May Also Like

-

Spot Danfoss Piston Pump JR-L-S75C-LS-21-25-NN-N3-S1NE-A2NNNN-JJ J-NNNNegotiableMOQ: 1 Piece

-

M, AH, HH Series Slurry PumpNegotiableMOQ: 1 Piece

-

Japan Komatsu PC200-8 PC210-8 PC220-8 Excavator 708-2L-31430 Hydraulic Main Pump 7082L31430US$ 4000 - 5000MOQ: 1 Unit

-

Automatic Pressure Control Water Pump for Irrigation SystemsUS$ 80000000000 - 100000000000000000MOQ: 1000 Tons

-

Rexroth PGF1-21/1.7RA01VP1 Type Hydraulic Internal Gear PumpUS$ 120.36 - 229.87MOQ: 1 Set

-

Innovative CMO GHIBLI FOOT PUMP Industrial Solutions for Enhanced PerformanceNegotiableMOQ: 1 Set

-

Manufacturer Direct Selling Fluorine Lined Strong Acid and Alkali Resistant Pump IHF Series Fluorine Plastic Alloy Chemical Centrifugal PumpUS$ 150 - 1600MOQ: 10 Pieces

-

Sand Pumping PumpUS$ 410 - 700MOQ: 1 Piece

-

Micro Machining Precision Casting Water Pump Spare PartsUS$ 1 - 30MOQ: 500 Pieces

-

Parts Of Breast PumpUS$ 1,000 - 1,100MOQ: 2 Tons