Bauxite roasting furnace for ceramic proppant

Bauxite ore introduction:

Bauxite, an aluminium ore, is the world's main source of aluminium. It consists mostly of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH) and diaspore α-AlO(OH), mixed with the two iron oxides goethite and haematite, the clay mineral kaolinite and small amounts of anatase TiO2.

What is ceramic sand?

Ceramic sand also called ceramic proppant, hydraulic fracturing sand, oil fracturing proppant, ceramic sand, bauxite ceramic proppant,

bauxite proppant, is used in the construction of deep well fracturing to increase the oil and gas production output as well as to extend

the oil and gas well’s service life.

Bauxite roasting furnace consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc.

Bauxite roasting furnace technical parameter:

| Model(m) | Diameter (m) | Length(m) | Slope(%) | Capacity(t/h) | Rotate Speed (r/min) | Motor Power(kw) | Weight(T) |

| φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

| φ1.6×33 | 1.6 | 33 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 50 |

| φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

| φ1.8×32 | 1.8 | 32 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

| φ1.8×45 | 1.8 | 45 | 4 | 2.8-3.34 | 0.21-2.11 | 30 | 95.2 |

| φ1.9×36 | 1.9 | 36 | 3.5 | 1.2-1.7 | 0.29-2.93 | 30 | 86.3 |

| φ1.9×45 | 1.9 | 45 | 3.5 | 1.65-2.5 | 0.29-2.93 | 37 | 109 |

| φ2.2×48 | 2.2 | 48 | 3 | 1.9-2.1 | 0.98-2.93 | 55 | 141 |

| φ2.5×40 | 2.5 | 40 | 3.5 | 6.0-7 | 0.44-2.44 | 55 | 139.61 |

| φ2.5×50 | 2.5 | 50 | 3.5 | 7.0-8.0 | 0.48-1.44 | 55 | 179.6 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 8.0-8.6 | 0.48-1.44 | 55 | 196.29 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 11-12.5 | 0.80-2.39 | 55 | 198.6 |

| φ3.0×45 | 3 | 45 | 3.5 | 13.3-16.9 | 0.5-1.35 | 55 | 223 |

| φ3.2×52 | 3.2 | 52 | 3.5 | 16-18.5 | 0.48-2.44 | 110 | 278 |

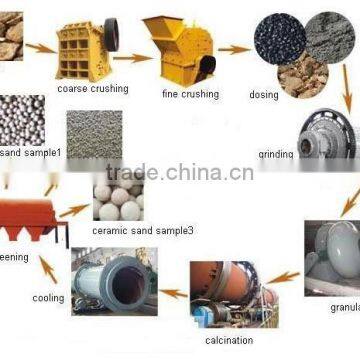

Bauxite roasting furnace production line :

Bauxite will be firstly crushed by jaw crusher and hammer crusher and then it will be conveyed to batching silo.

After batching with other material, materials will be sent to ball mill and grinded into powder. Classifier will be used after ball mill for size grading. Here raw material will be sent to silo again.

Then raw material will go to granulator and will be made into different size pellets. Pellets will be sent to screening equipment. Qualified size pellets will be conveyed to rotary kiln for calcination. Oversize pellets will be sent back for grinding.

After pellets calcined in rotary kiln, we get qualified product ceramic sand. At last, ceramic will go to cooler for cooling. And will go to screen to get different size oil fracturing proppant and will be packed in ton bag. The production process ends.

1.Crushing:

Bauxite mining, fragmentation is generally around 300 ~ 500mm, containing a small amount of water. Generally use jaw

crusher, hammer crusher, secondary crusher system, and its size controlled below 8mm.In the process for the production

of ceramic sand, Mn element is usually added to reduce the sintering temperature and dyed dark.

2. Raw materials preparation:

Bauxite, manganese powder,etc. were transported to their respective databases, the library set the speed

belt weighing the material in automatic dosing.

3. Grinding ball mill:

Ball mill grind the raw materials into fine powder.

Drying material of the hot air from the exhaust of the rotary kiln, so that the utilization of waste heat, set up a dedicated stove.

4. Ball making machine:

Raw material powder into a small hopper, silo set screw metering device or speed belt weighing device, measuring raw feeding amount. The raw material into ball making machine. Meanwhile, the flow meter can measure water pipeline pump to spray water into the inside of the ball making machine. Rotation of the ball making machine can make various size of ball.

When ball discharging, by the belt conveyor into the screening device and qualified into the rotary kiln, too big materials go back to raw material grinding processes.

5. Calcining by Bauxite roasting furnace

Feed the ball into the rotary kiln with a certain slope for calcination, with the rotation of the Bauxite roasting furnace , feed the ball to scroll to the kiln head, pulverized coal from the kiln hood sprayed into the kiln burning, pellet in the rotary kiln to be calcined into high strength ceramic sand.

6. Coal burner

Coal burner for offering heat source for Bauxite roasting furnace .

7.Final ceramic sand cooling

8.Screening and packaging ceramic sand

Cooled ceramic sand can be directly transported to the multi-level vibrating screen, divided into different grades.

Derui main products:

Crushing equipment: jaw crusher, impact crusher, cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen;

Mineral processing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Drying equipments: sawdust dryer, wood chips dryer, sand dryer, coal dryer, mine powder dryer,etc.

Building material equipment: rotary kiln, lime rotary kiln, cement rotary kiln, rotary kiln bauxite , Ceramic sand rotary kiln ,etc.

Production line: sand production line, stone production line, active lime production line, cement production line.

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Separator Rotar Cement Mill Liner PlateUS$ 256 - 256MOQ: 1 Piece

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set