Iron ore grinding machine manufacturer in China

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, deep purple, to rusty red. The iron itself is usually found in the form of magnetite (Fe3O4, 72.4% Fe), hematite (Fe2O3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH).n(H2O)) or siderite (FeCO3, 48.2% Fe).

Iron ore grinding machine is a type of grinder used to grind iron ore into extremely fine powder.

Iron ore grinding machine is the key equipment for grinding crushed materials, and it is widely used in production lines for powders

such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and

non-ferrous metals.

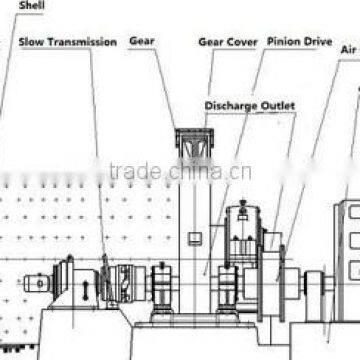

Iron ore grinding machine is composed of the feeding part, discharging part, turning part and driving part (reducer, small transmission gear, motors,

electrical control) and other components.

Iron ore grinding machine consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a

small angle to the horizontal. it is partially filled with balls.

Iron ore grinding machine Working principle:

Iron ore grinding machine works on the principle of impact: size reduction is done by impact as the balls drop from near

the top of the shell.

In case of continuously operated Iron ore grinding machine, the material to be ground is fed from the left through 60° cone and the product is

discharged through a 30° cone to the right. As the shell rotates, the balls are lifted up on the rising side of the shell and then

they cascade down (or drop down on to the feed), from near the top of the shell. In doing so, the solid particles in between

the balls are ground and reduced in size by impact.

Iron ore grinding machine technical parameter:

| Model | Rotate speed(r/min) | Ball weight | Feeding size(mm) | Discharing size(mm) | Output | Power(kw) | Weight(t) |

| (t) | (t/h) | ||||||

| Φ900×1800 | 42 | 1.4 | ≤20 | 0.075-0.89 | 0.65-2.0 | 15 | 3.6 |

| Φ900×2100 | 41 | 1.7 | ≤15 | 0.075-0.83 | 0.7-3.5 | 18.5 | 3.9 |

| Φ900×3000 | 41 | 2.5 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.5 |

| Φ1200×2400 | 36 | 3.5 | ≤25 | 0.075-0.6 | 1.5-4.7 | 30 | 11.5 |

| Φ1200×2800 | 36 | 4.5 | ≤25 | 0.075-0.6 | 1.5-5.0 | 37 | 12.6 |

| Φ1200×4500 | 32 | 5.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500×3000 | 31 | 6.8 | ≤25 | 0.074-0.4 | 2.0-7.0 | 75 | 17 |

| Φ1500×3500 | 31 | 7.75-6.4 | ≤25 | 0.075-0.4 | 3.0-8.5 | 75 | 17.5 |

| Φ1500×4500 | 27 | 10.5 | ≤25 | 0.074-0.4 | 3.5-8.0 | 110 | 21 |

| Φ1500×5700 | 27 | 13 | ≤25 | 0.074-0.4 | 3.5-10 | 130 | 24.7 |

| Φ1830×3000 | 26 | 18 | ≤25 | 0.074-0.4 | 4.0-12 | 160 | 28 |

| Φ1800×3600 | 26 | 10.6-11.35 | ≤25 | 0.075-0.4 | 5.0-13 | 160 | 33.5 |

| Φ1830×4500 | 26.5 | 12 | ≤25 | 0.075-0.6 | 5.5-20 | 185 | 35 |

| Φ1830×7000 | 26 | 22 | ≤25 | 0.074-0.4 | 6.5-22 | 210 | 38 |

| Φ2100×3600 | 24 | 14-15.2 | ≤25 | 0.075-0.4 | 15-30 | 185 | 46.8 |

| Φ2200×5500 | 21 | 30 | ≤25 | 0.074-0.4 | 10-20 | 245 | 48.5 |

| Φ2200×6500 | 21 | 31 | ≤25 | 0.074-0.4 | 14-50 | 380 | 52.8 |

| Φ2200×7500 | 21 | 33 | ≤25 | 0.074-0.4 | 16-50 | 380 | 56 |

| Φ2400×3000 | 20.6 | 15.5-16.6 | ≤25 | 0.075-0.4 | 15-55 | 245 | 59 |

| Φ2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 15-60 | 380 | 65 |

| Φ2700×3600 | 20.6 | 39 | ≤25 | 0.074-0.4 | 20-70 | 400 | 91.3 |

| Φ2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 20-80 | 400 | 94 |

| Φ2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 20-90 | 430 | 102 |

| Φ3200×4500 | 18 | 65 | ≤25 | 0.075-0.4 | according | 800 | 137 |

Application of Iron ore grinding machine:

Iron ore grinding machine in Cement production's process:

Cement Crusher -->Preparation of raw material --> Raw material homogenization -->Preheat decomposition --> The burning of

cement clinker-- > Cement grinding mill (Ball Mill)> Cement Packaging.

5000TPD Iron ore grinding machine production line:

Feeder(900*1200)------Jaw crusher(900*1200)------conveyor------Jaw crusher(300*1300)------Bucket elevator(HL500)------Silo(200m³)------Iron ore grinding machine(3200*5500)------Magnetic separator(1500*2400)

Packaging and shipping of Iron ore grinding machine:

Packaging

1.Sand blasting, coated with high quality paint

2.Nude packing or load container for main machines

3.Motors and spare parts in plywood cases

Shipping

1.FOB port: Qingdao, Tianjin, or as your requirement

2.Delivery date: Within 30-45 working days

3.We will remind you before boat arrival

Payment term of ball mill:

1. We usually accept TT, L/C.

2. TT: 30% in advance as down payment, the balance before delivery

3. We take pictures of finished products before delivery.

Send Inquiry to This Supplier

You May Also Like

-

Lab Mill Triple Grinding Machine For TestingUS$ 656 - 3,640MOQ: 1 Set

-

Ball Mill Jar With Capacity of 0.56-130TPH and ISO9001:2008 CertificateNegotiableMOQ: 1 Set

-

Mineral Gold Ore Copper Ore Complete Chrome Ore Processing Line for AlbaniaUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill /pan Mill /wet Grinder Made in HuahongUS$ 1,000 - 8,000MOQ: 1 Set

-

Hot Sale Carbon Black Grinding MachineUS$ 1,900 - 3,500MOQ: 1 Piece

-

China Bank Account OpeningNegotiableMOQ: 1 Set

-

KMJ02-05 Stone Grinding Ball MachineNegotiableMOQ: 1 Unit

-

China Top 10 Chocolate Ball Mill With Quality CertificationUS$ 5,000 - 60,000MOQ: 1 Set

-

China BV CE Certificates Mining Stone Impact Crusher Machine Manufacture SupplierUS$ 1,000 - 1,000MOQ: 1 Set

-

Vertical Roller MillUS$ 40,000 - 150,000MOQ: 1 Set