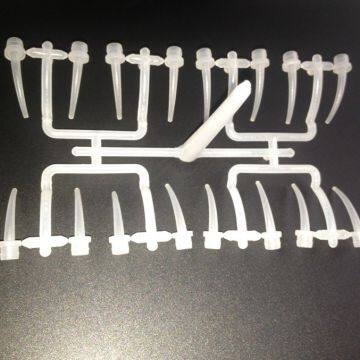

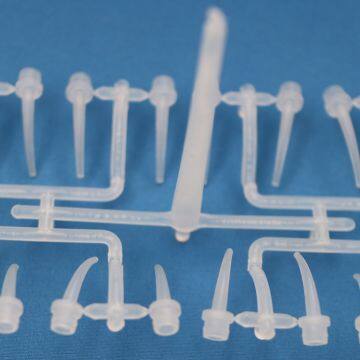

Dental Plastic Part Molding & Tooling

BHM offer custom tooling and injection molding service for dental products in dentistry market.

Our Mold tooling servces small and delicate dental parts, like what we will show you , as well as tooling & OEM production for large volume plastic part for dental equipment.

Best Hope Mold & Plastic (Shanghai) Co., Ltd (BHM) focus on high precision Plastic Injection Molds design and developing, as well as custom injection molding.

BHM's Facilities:

BHM owns three facilities located in Shanghai and Suzhou, respectively focuses on High Precision Molds, Medium-sized Molds and Large Volume Molds.

Since established in 2005, BHM has been developing very fast, business expands rapidly due to quality products and serves, At present, BHM has covers an area of 10000m2 in total and owns 185 employees including 28 engineers, 110molds makers,10 QC personnel and many injection operators.

BHM's Capabilities:

BHM offer one-stop services from engineering design, tooling , to custom injection molding, as well as printing and assembly etc.

Design for manufacturability and efficient production is our primary objective. The mold drawings can be finished within 2-4 days then send to customer for checking before tooling. We are able to meet our customers' shortened lead time. All the necessary technical drawings will be sent to customers for future mold maintenance references.

Our high speed milling machine, EDM, WEDM and CMM optimize our tooling process and improve accuracy and efficiency of our mold to ensure customers can get quality product.

Our expertise in tooling leads to better results in molding. We have 11 injection machines for mold trial, mold validation and custom production.

We have enough experience working with materials such as: LDPE, HDPE, PP, ABS, PC, PS, PVC, PA, PMMA, POM, TPU, TPR, TPE ETC.

| Name | Injection Mould for Dental Plastic |

| Engineering | CAD, UG, ProE, CAD, Solidworks, Mastercam, Cimatron^ |

| Core/Cavity Steel | 1.2316, 1.2083, 1.2344, ASSAB S136 ESR, H13, hardening, HRC52-54 |

| Mold Base | LKM (or according to customer) |

| Mold Spare Parts | DME, HASCO, MISUMI, LKM ^standard |

| Cavity No. | Multi cavity: 16/24/32/48/64^ |

| Runner | Hot, Hot to Cold, Cold |

| Hot Runner Brand | Husky, YUDO, Mold Masters, Synventive, Mastip^ |

| Demoulding | Motor, oil cylinder, stripping plate, slides, angel pin, ejector sleeves ^ |

| Mold Life | 100, 000 - 5000, 000 shots |

| Lead Time | 3-10 weeks according to complexity of mold |

| Packaging | Fumigation-free wooden box |

Send Inquiry to This Supplier

You May Also Like

-

Moulds of Anesthesia Breathing Circuit AccessoriesUS$ 1 - 2MOQ: 5000 Pieces

-

Oxygen Concentrator Humidifier Bottle MouldsNegotiableMOQ: 5000 Pieces

-

Moulds for AV Fistula NeedleUS$ 1 - 2MOQ: 5000 Pieces

-

High Efficient Short Delivery Flip Top Cap Injection Mold With in Mold FoldingUS$ 1 - 1MOQ: 5000 Pieces

-

Male / Female Luer Lock Injection Mold With High QualityUS$ 0.1 - 1MOQ: 5000 Pieces

-

Disposable Medical Syringe Barrel Injection Mold With High Quality ControlNegotiableMOQ: 1 Piece

-

Medical Plastic Y Connector Injection MouldUS$ 0.1 - 1MOQ: 5000 Pieces

-

I. V. Clamp Mold/Roller Clamp MouldsUS$ 0.1 - 1MOQ: 1 Piece

-

High Precision Oxygen Tube Connector Injection MouldUS$ 0.1 - 1MOQ: 5000 Pieces

-

Plastic Soft Test Tube With Rubber Tube Cap, Injection TubeUS$ 0.1 - 1MOQ: 1 Piece