5-15 Concrete Hollow Brick Machine Price/hollow Block Machine/concrete Blocks Making Machine

LK5-15 Hydraulic automatic concrete brick making machine's ancillary equipments

As shown , this is a complete production line. It mainly includes 11 links , the brick maing machine use German technology.

Video link:

Testing LK5-15 brick making machine, brick model is "U".

https://youtu.be/b09WOJXy6co

Testing LK5-15 brick making machine, double layout material, Green square brick.

https://youtu.be/b5uqZhNk8Kw

1.Product Application

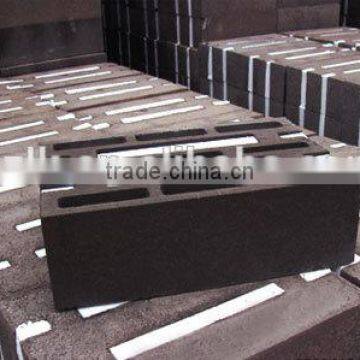

LK 5-15 brick making machine can produce bricks of different size and colorbrick, including trails brick, square brick, lawn brick, paver bricks, planting bricks, protecing-slope bricks, road-rim bricks, hollow brick, standard brick and porous brick and so on.

LK 5-15 brick making machine has the versatility, it can meet the demand of market, the investment for equipment is less,

simple operation, it is a kind of economical machine, it can reduce the investment risk to the greatest extent.

2.Main Features

1) Hydraulic automatic brick making machine.

2) Multifunctional brick making machine.

3) Easy in installation and maintation, PLC control , simple operation.

4) Molding cycle is short , high efficiency .

5) Auxiliary equipment is complete, high degree of automation.

LK5-15 concrete brick/block making/moulding machine

1.PLC

1)PLC is the control center of production line , it control mixer , conveyor , host and palletizing machine .

2)PLC is Japan's mitsubishi technology , The screen can touch,It can set up automatic operation and manual operation.

3)In generally , If PLC fails , we can use manual operation.

2.Pallets Feeder

Pallets feeder can realize to convey one after another of the plate to the molding machine automatically.

Because PLC can pallets feeder by hydraulic equipment.

1)Pallet box. Storage pallet.

2)Pulley. When workers placed the pallets into the pallet box , workers can save energy.

3)Angle iron. On both sides have the angle iron , they have strengthen and fixed role in pallet box.

It effectively prevent the deformation.

4)Pusher. Push pallet into the machine.

5)Hydraulic cylinder. The conditions of the automation.

6)Pallets feeder interior structure.

3.Screw Type Concrete Spreader

It adopts hydraulic screw principle , a greater degree of improve the effect of arrangement of raw material.

1)Hydraulic cylinder. The conditions of the automation.

2)Hairbrush.Cleaning undersurface of pressure head, to ensure the quality of the finished product.

4.Pressure Head And Mould

5.Block Conveyor Machine

Finished product from brick machine to palletizers, machine to roperation automatically.

6.Palletizing Machine

2)Drive motor. Horizontal motion.

3)Position transducer. Position sensor , automatic stop.

4)Secondary protection angle iron. When induction didn't respond , it will stop the machine horizontal motion.

5)I-shaped rail.I-shaped rail fastness, durable and wear-resisting, driving safety and steady.

6)Electromotor hood. Closed operation, avoid winding wire and wire.

1.Hydraulic work, high degree of automation.

1)Hydraulic tubing. Use special synthetic rubber, has excellent oil resistant, heat resistant, aging resistant performance.

Hydraulic tubing high bearing pressure, pulse superior performance.Tube body combined with close, use soft, small

deformation under pressure.The hydraulic tubing has excellent resistance to curve around sex and fatigue resistance.

2)Solenoid valve. High efficiency, good quality, long service life.

3)Pump.The core of the hydraulic pump station components, performance is good, good quality.

4)Equipotential connection terminal box and water cooling equipment.

2.High efficiency, multi-function.

The machine has a set of mould, if you need to customize other mould, you need to pay extra.

3.Focus on the details,valuable on the precision.

Different orientation diagram.

Front view of machine.

Vibration equipment and Synchronous rack.

1)Vibration box.

2)Shock absorption pad.

3)Synchronous rack.

Company :

Zhengzhou Lianke Machinery Manufacture Co., Ltd. is located in xiaobei industrial park,zhengzhou city, henan province,China.Covers an area of nearly 27000 square meters,construction area of 18000 square meters,its annual sales exceed 150 million yuan,to earn foreign exchange through exports of $6.8 million.From 1985 to 2016, Zhengzhou Lianke Machinery Manufacture Co., Ltd. passed more than 20 years, today, Zhengzhou Lianke Machinery Manufacture Co., Ltd. equipment has spread throughout the country, equipment is approved by the national people's, harvest many honors.And hot sale overseas,exported to North America, South America, Latin America, Africa, Europe, Australia.

QUALITY ASSURANCE: The guarantee of the whole machine is one year, not including man-made damage.

Our service: Engineers overseas installation services.

Packing Details : Export standard packing, LCL or FCL.

Delivery Details : 15-25 days after deposit is received.

After you pay a deposit in advance, we will prepare the goods for you at the fastest speed and we will update your order information at any time, we will use pictures, video and other ways to let you know your order execution situation.

QMJ 4-35A

QMJ 4-35C

QT 3-15

We can give you only service attitude, product quality, good price and a happy cooperation.

Here can copy

Phone or WhatsApp: +8613137159909

Wechat or Viber: +8613137159909

We can provide high quality service to you,

and good quality and price.

Skype: live:alan_8374

TradeManager: cn1511903408

Website:

Your friend Alan

Send Inquiry to This Supplier

You May Also Like

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Hot Sale Cement Interlocking Brick Making Machinery Automatic Hollow Concrete Block Making Machine China Brick Machines for Construction JobsUS$ 499 - 2256MOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece