Soybean Oil Refining Process

Henan Doing Company adopts the most advanced CE and ISO9001 approval continuous soybean oil refining process line to get high purity and high oil yield refined soybean oil. Available with both physical and chemical refinery technology, we are able to provide customers the most affordable soybean oil refining machines including design, manufacturing, installation with guaranteed quality and reliable service.

Soybean oil refining machine

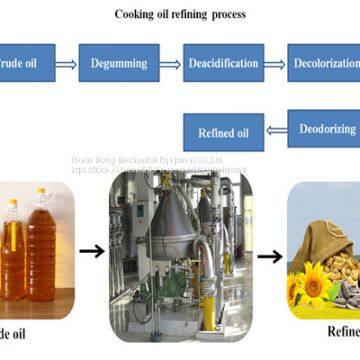

General introduction of crude soybean oil refining process technology:

● Advanced techniques applied soybean oil refining production line with high efficiency and low residual oil.

Henan Doing Company is focusing on designing physical and chemical edible oil refining process through de-mixed, degumming, dehydration, deacidification, decoloration, dewax and deodorization, oil pumps, filter system to obtain high purity refined soybean oil.

Soybean oil refining process

1) Soybean oil refining section adopts p-acid degumming, alkali refining de-acid and water rinsing to complete primary soybean oil refining.

2) Decoloring section will remove off pigments, blenching oils and grease dehydrate in crude soybean oil, and deodorizing section will remove off the odor component in oil.

3) Dewaxing section will remove wax in crude soybean oil to obtain high quality oil refinery.

4) Heat conducting oil boiler supplies each device energy and its highest temperature can reach above 280°C.

5) Steam generator produces the required steam for deodorization and distillation.

6) Vacuum pump supply vacuum for dehydrate, de-color, de-odor with high vacuum degrees of 755mm Hg.

7) Air compressor dries the blenched clay and empties the leftover oil in the press filter.

● Professional designed soybean oil refining process line assures high soybean oil capacity. The application of auto welding machine, professional designed thermometer, pressure gauge, safety valve, and vacuum system ensure the most secured refining of crude soybean oil with low residual oil and low pollution.

Contact us:

Contact:Miss Sophia Zang

Skype:sophia.zang1

Mobile:+86 13526627860

Phone:+86-371-5677 1823

Website:

E-mail: oilmachine@doingoilmachine.com

Send Inquiry to This Supplier

You May Also Like

-

5-20tpd Edible Oil Refinery EquipmentUS$ 15000 - 35000MOQ: 1 Set

-

Widely Used Vegetable Oil Refining MachineUS$ 15000 - 35000MOQ: 1 Set

-

Batch Type Edible Oil Refining Machine,edible Oil Refining ProcessUS$ 15000 - 35000MOQ: 1 Set

-

Cooking Oil Refining Machine for Peanut Soybean Sunflower OilUS$ 15000 - 35000MOQ: 1 Set

-

30-50tpd Corn Germ Oil Refining Machine ,cooking Oil Refining Production LineUS$ 15000 - 35000MOQ: 1 Set

-

Mini Palm Oil Refining Machine,palm Oil Refining Production LineUS$ 15000 - 35000MOQ: 1 Set

-

Penaut Groundnut Oil Refining Machine, Edible Oil Refining MachineUS$ 15000 - 35000MOQ: 1 Set

-

Cooking Oil Refining Machine for Peanut Soybean Sunflower OilUS$ 15000 - 35000MOQ: 1 Set

-

Physical Refining and Chemical Refining of Edible OilUS$ 15000 - 35000MOQ: 1 Set

-

Palm Oil Refinery Plant , Machine to Refine Crude Palm OilUS$ 15000 - 35000MOQ: 1 Set