PLATE HEAT EXCHANGER Plate Cooler

PLATE HEAT EXCHANGER is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air.

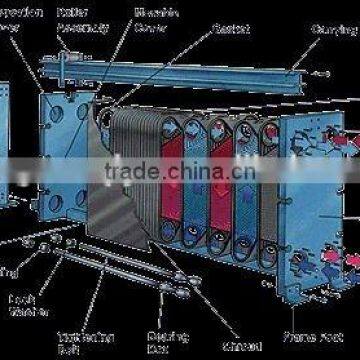

Plate Heat Exchangers

The plate heat exchanger consists of a frame, which consists of a head, follower, column, carrying bar, guiding bar, and a number of clamping bolts. In between head and follower a varying number of pressed plates are clamped together.

Each plate is supplied with a gasket, so that the plates form a closed system of parallel flow channels, through which the medias flow alternatively at every second interval.

The Plate Stack - Medie

The gaskets are glued on the plates, securing tightness between medias and the atmosphere. Between the different medias there are double gaskets, which have intermediate drain areas, meaning that mixing of the two medias is impossible.

Every second plate in the stack has to turn 180°, so that the plates form a closed system of parallel flow channels, through which the medias flow alternatively at every second interval.

Gasket Construction - New Gaskets

The first plate after the head and intermediate frames is mounted with a gasket in all the gasket grooves.These gaskets are cut out of ordinary gaskets.

Glue Less or Glued Gaskets

Some plate heat exchangers are delivered with glue less "Sonder Snap" gaskets. In these units it is possible to change the gaskets without using glue. However, the gasket on the first plate after the head and intermediate frame should be glued on in the pattern displayed above.

Send Inquiry to This Supplier

You May Also Like

-

Japan Saginomiya ATX-71110DHS/DUS/DHG ATX Series Thermal Expansion ValveUS$ 10 - 15MOQ: 1 Piece

-

Sanhua Parts DPF-TS/S Series Electronic Expansion ValveDPF(S03)4.0C-01 PQ-M03012-000012US$ 70 - 300MOQ: 1 Piece

-

SPRLAN Thermal Expansion Valve FBVE-6CP100 6 Cold Stamping (1/2*5/8*1/4 76CMUS$ 70 - 300MOQ: 1 Piece

-

SPRLAN Thermal Expansion Valve FBVE-6CP100 6 Cold Stamping(5/8*7/8*1/4)152CMMUS$ 70 - 300MOQ: 1 Piece

-

SPRLAN Thermal Expansion Valve FBVE-3-Z FBVE-1.5-Z Refrigeration AccessorieUS$ 70 - 300MOQ: 1 Piece

-

SPRLAN S.P.R.L.AN Thermal Expansion Valve FJE-1-C 1 Cold Hammer, Refrigeration Unit Spare Parts Air ConditioningUS$ 70 - 300MOQ: 1 Piece

-

SECOP Refrigerator Air Conditioner Refrigeration Compressor SC21CNX.2US$ 70 - 300MOQ: 1 Piece

-

Castel Valve Solenoid Valve 1078/5 1078/4A6 Refrigerate PartsUS$ 70 - 300MOQ: 1 Piece

-

DunAn Shield Electromagnetic Valve Refrigeration Equipment FDF3-1002 FDF10-1002 FDF6-102US$ 300 - 8000MOQ: 1 Piece

-

DunAn Shield Electromagnetic Valve Refrigeration Equipment Air Conditioning Solenoid Valve FDF3-1002 FDF15-1002 FDF10-1002US$ 300 - 8000MOQ: 1 Piece