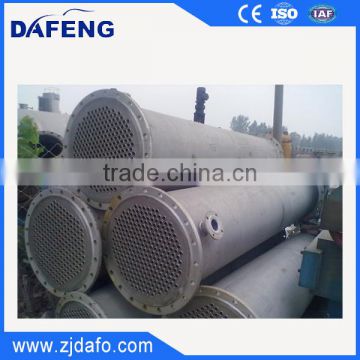

This product tubular heat exchanger, is widely used in fluid heat

exchange of the drugs-manufacturing, chemistry and industry, food, spin-

ning and weaving profession. According to the different procedure, there

are two kinds of material: 316L and 304. the inside and outside of the heat

exchanger is polished Ra 0.45 and the whole inside is treated with deactivated

processing. It can also be used to kill the bacteria wilh pure vapor

according to the procedure.

Due to its good sealing, wide applicable condition and not easy pollution, it is especially suitable for the heal transfer of infusion,

the water needle the freezing and drying powder injection in the drugs manufacturing profession, and the purification water, the injection water in the process of biological

preparations, as well as for the rising and decreasing temperature of medicine fluid.

It also can make a special design according to the material and special

requirement from the customer' s procedure, and it can manufacture heat exchanger 1 - 200 m².

etailed introduction to Shell & Tube Condenser (Heat Exchanger):

U Condenser (heat exchanger) are designed to provide our clients the best solutions available in Refrigeration applications.

Its main function is to condense the refrigerant from steam into liquid. The shell and tube part is made of high performance tubes Q235-B, steel 20# etc. and its coppers tubes with grooves both outside and inside to achieve best efficiency.

1, A Series (Ranging from 11,340Kcal/h to 831,600Kcal/h): Matching for single compressor unit.

2,B Series (Ranging from 37,800Kcal/h to 1,134,000Kcal/h): Matching for double compressors unit.

3,C Series (Ranging from 56,700Kcal/h to 340,200Kcal/h): Matching for triple compressors unit.

Suitable for R22, R134A, R407C, R410A, R404A, etc. Please contact us for more details.

Specification(m2) | Effective Length (mm) | O.D (mm) | Weight (kg) |

0.5 | 800 | 159 | 60 |

1 | 800 | 159 | 90 |

1.5 | 1200 | 208 | 138 |

2 | 1200 | 220 | 155 |

3 | 1400 | 300 | 236 |

5 | 1200 | 300 | 260 |

10 | 1600 | 400 | 390 |

15 | 2400 | 400 | 560 |

20 | 2600 | 400 | 800 |

30 | 3200 | 450 | 1005 |

40 | 3500 | 500 | 1310 |

50 | 4000 | 500 | 1620 |

60 | 4000 | 500 | 1850 |

70 | 4000 | 500 | 2080 |

80 | 3500 | 600 | 2320 |

90 | 4000 | 600 | 2600 |

100 | 3000 | 700 | 2950 |

Our company’s advantages over other companies:

Advanced Technology Co., Ltd Wenzhou is the a professional Stainless steel Mixing Equipment,Tank Pressure Vessels,Filters,Beer equipment and brewing technology supplier, who can professionally design, research and develop, and manufacture these equipment.

We can provide clients one-stop service from design, layout, to finished products. Its main business includes beer equipment, self brewing equipment, hotel beer equipment, draft beer dispenser, school laboratory equipment, etc. We mainly provide the capacity 500L/DF, 1000L/DF, 2000L/DF, 3000L/DF, 5000L/D,10000L/D,20000L/D etc.

Our staff of Sales and Technical Support is available to help you in selecting the right protection for your application as well as to provide you with Samples of our products for evaluation. At Advanced Tech., we are committed to providing the Highest level of customer service, Competitive pricing, Speedy delivery and a Comprehensive, cutting-edge product offering. Our ultimate goal is your satisfaction.

Our company’s quality certification:

We have got CE, PED, ISO9001 (2008) certificates. If necessary, we can offer electronic record’s certificates but the original document must be kept in the company.

Our company’s customer segmentation:

Our customer segmentation is mainly focused on the European,American developed countries such as the USA,Canada, Lati-America,the United Kingdom, Australia,

Saudi Arab and Asia etc. At present,we are looking for superior agents to create a brilliant future.

Shipment

Bulk cargo: standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the equipment’s surface.

Container cargo: equipment will be bound firmly,won’t easily swing to the side, or up, or down.

Send Inquiry to This Supplier

You May Also Like

-

Rotary Refrigeration CompressorUG5T450FUEJX、UG5T450FUFJX、UG5TM5520FJX、UG8T265FXAEWUS$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorJPV066AC-4X9-520、JPW066AC-4X9-520、JPW079AC-4X9-002US$ 3000 - 6000MOQ: 1 Piece

-

Rotary Refrigeration CompressorJPW053AC-4X9-520、VPV030SE-3X9-582、VPV038SE-3X9-582、VPV038SE-4X9-582US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorVPV038SE-9X9-524、VPW038DE-3X9-571、VPW038SE-3X9-582、VPW038SE-9X9-570US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorYAW112AT-4X9-EBX、YPV112AT-4X9-EBX、ZPV0382E-2E9NDEV、ZP038SE-4X9-524US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorZPV050DE-3X9-571、ZPV0631E-5X9-522、ZPV0662E-4E9-XXXUS$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorZPV0662E-4X9-522、ZPV0802E-4X9-522、ZPV0962E-4X9-522US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorZPV096-7E9-SAMPIE、ZPV112AE-4X9-550、ZPW038SE-4X9-524、ZPW112AE-4X9-550US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorZB15KQE-TF5-524、ZB19KCE-TF5-524、ZB21KQ-TF5-524US$ 3000 - 6000MOQ: 1 Piece

-

Refrigeration CompressorZB26KCE-TF5-524、ZF09K4E-TF5-231、ZF09K4E-TF5-550US$ 3000 - 6000MOQ: 1 Piece