Quartz sand production line 20-500t/h :

All kinds of general specification of the quartz sand production line: 0.5-1.0mm 0.6-1.2mm 1-2mm 2-4mm 4-8mm 8-16mm 16-32mm. Also can produce special specifications according to customers requirements, the requirements for particle size distribution can be processed.

1) Firm structure, stable performance, large capacity, even producing granularity.

2) With the increase of production, our jaw crusher can greatly reduce the operating costs.

3) Convenient maintenance and economical running expense.

4) The large feed opening and force-feeding action from the inward and downward eccentric movement of the swing jaw mean that our jaw crusher can increase the capacity.

Quartz sand production line consists of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, dryers and other major equipments, cooperate with the rock feeder, hoisting machine, transfer machine can form a complete beneficiation production line. This production line has high efficiency, low energy, high capacity, reasonable economy, etc.

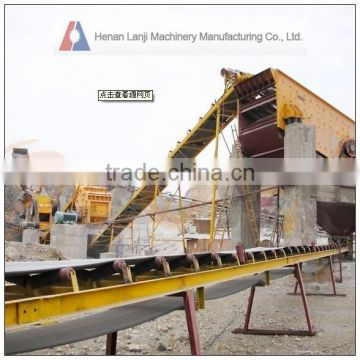

Stone production line basic introduction:

The stone production line flow produced by our LanJi corporation is consist of hopper, vibrating feeder, jaw crusher, impact crusher, vibrating screen and belt conveyor ect. According to your specific requirements, we can design different type production lines, and we are capable to provide you the best technical support all-around.

Stone production line process:

First the raw materials be send to primary crusher(jaw crusher) by vibrating feeder, after first-stage crush, material will be transport to the secondary crusher(impact crusher) by belt conveyor, to get the rather fine size gravel, then these products be separated by vibrating screen to meet the size customer request.

Quarta sand Stone production line is usually decided by several factors:

1) Raw materials to be crushed.

2) The hardness, percentage of Si, moisture percentage of the raw materials.

3) The average size of the raw materials before entering into the crushing system.

4) Requested product sizes, percentage of the sizes, and their usage.

5) Crushing capacity per hour for this whole line.

Small size can by packed by wooden case, medium size can ba packed by container and large size can be shipped in bulk.

(1) Design for production line flow and equipment layout for free according to the site condition.

(2) Supply the foundation drawing of equipment and drawing of parts made by buyer.

(3) Supply the technical parameters of peripheral equipment.

(4) During the operation, we can offer the technology service freely if the user needs to adjust the layout and application.

(5) During the operation, we only collect the cost if the user willing to upgrade the equipment when we havethe advantagetechnology.

Thanks so much for you taking time to browse our quarry plant. Any further questions, please feel free to contact us and we are ready to so service for you!

Contact:

Ms Sara

Mobile phone(whatsapp) : 008613783471727

Skype : sarapang6

Send Inquiry to This Supplier

You May Also Like

-

High Efficiency Crushing Plant Mobile Jaw Crusher Station NK75J for Mining Industry WorkNegotiableMOQ: 1 Set

-

Bimetal Overlay Wear Plate for Crusher Main Frame LinersUS$ 100 - 100MOQ: 1 Piece

-

Car Bodies Shredder Waste Car Logger Car Shell Compactor Car Body Baler Metal Baling MachineNegotiableMOQ: 1 Set

-

Electric Start Mobile Crusher Factory Outlet 18KW 1003086 for Sale Max.20t/h 10 Woking Days After Received The DepositNegotiableMOQ: 1

-

Rock Crusher Machine Price/Mini Hammer Mill Crusher For Coal Heavy DutyUS$ 560 - 8,600MOQ: 1 Set

-

PebblesNegotiableMOQ: 1 Kilogram

-

Precision Mechanical ComponentsNegotiableMOQ: 1 Kilogram

-

Lateral Parts And OtherNegotiableMOQ: 1 Kilogram

-

Chute FeederNegotiableMOQ: 1 Kilogram

-

Roll Crusher Used in Mining, Smelting, Building Material, Highway, RailwayUS$ 3,000 - 10,000MOQ: 1 Set