Copper ore beneficiation processing mining plant :

Copper is one of valuable nonferrous metals, which is mainly extracted from sulfide ores and some oxidized ores. Kefid provides our customers with plant designing and all the machines used in the plant, together with technologies, operation guide and perfect after-sale service.

The beneficiation methods and quality requirements of copper ore:

Flotation is main method of cooper ore beneficiation; some are also using with magnetic separation, gravity separation and wet smelting, etc.To choose the right method of beneficiation, we should study the components and structure of copper ore, and identify the type (natural and industrial) of copper, and know about the content of refractory minerals in the ore and its general distribution, etc.According to the different proportion of copper oxide and copper sulfide, The natural copper ore can be divided into sulfide ore (containing copper oxide below 10%), mixed ore (containing copper oxide, 10 ~ 30%) and oxidized ore (containing copper oxide more than 30%).

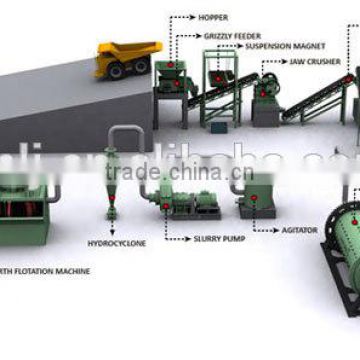

Copper ore beneficiation equipments include:

Vibrating feeder, belt conveyor, jaw crusher, cone crusher, ball mill, flotation machine, fine ore filtering machine and dryer.

In most cases, we apply flotation process for copper ore dressing and the generally process steps as following:

1. The raw copper ore material will be transported to crushing area, first fed into a jaw crusher for primary crushing and then output material goes into a secondary crusher, say cone crusher, to get small size copper ore. And the material then goes into a storage bin.

2. The crushed material in the storage bin is transported to a ball mill by a vibrating feed. Crushed copper ore then will be grinded to a certain size (according to ore’s characteristics) like pulp mixed with water and discharged into a fine ore pool.

3. The pulp first is pumped to a mineral agitation barrel for mixing with medicaments and then goes to flotation cells for concentrating. The final product goes to a filter and a dryer, to the ultimate we get dry fine copper ore with high grade which can be put into further process for copper extracting.

And of course, we can provide different copper ore processing plants according to copper ore’s different features and customers’ requirements. Giving our customers a most suitable, scientific, practical and satisfied answer is a goal we have been strived for.

Contact: Ms Sara

Mobile phone : 008613783471727

Skype: sarapang6

Send Inquiry to This Supplier

You May Also Like

-

High Efficiency Crushing Plant Mobile Jaw Crusher Station NK75J for Mining Industry WorkNegotiableMOQ: 1 Set

-

Bimetal Overlay Wear Plate for Crusher Main Frame LinersUS$ 100 - 100MOQ: 1 Piece

-

Car Bodies Shredder Waste Car Logger Car Shell Compactor Car Body Baler Metal Baling MachineNegotiableMOQ: 1 Set

-

Electric Start Mobile Crusher Factory Outlet 18KW 1003086 for Sale Max.20t/h 10 Woking Days After Received The DepositNegotiableMOQ: 1

-

Rock Crusher Machine Price/Mini Hammer Mill Crusher For Coal Heavy DutyUS$ 560 - 8,600MOQ: 1 Set

-

PebblesNegotiableMOQ: 1 Kilogram

-

Precision Mechanical ComponentsNegotiableMOQ: 1 Kilogram

-

Lateral Parts And OtherNegotiableMOQ: 1 Kilogram

-

Chute FeederNegotiableMOQ: 1 Kilogram

-

Roll Crusher Used in Mining, Smelting, Building Material, Highway, RailwayUS$ 3,000 - 10,000MOQ: 1 Set