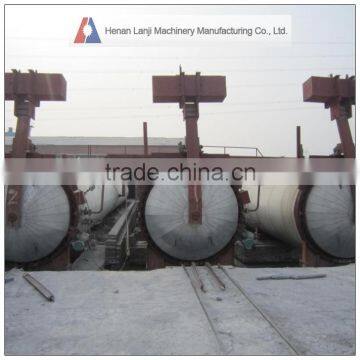

Autoclave for AAC Block Production Line

Autoclave for AAC block production line :

The autoclave uses widely applied to a large number of aerated concrete block, concrete pipe piles, sand-lime brick, fly ash brick and other building materials autoclave curing

Autoclave Features:

1 .Product weight is according to 600 kg/m3 to control.

2 .Annual capacity 200,000M3.

3 . Set raw material proportion: cement 6.5%, raw lime 23%, fly ash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4 .Water and material rate 0.631

5 .One mould product 2.88M3

6 .Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7.Casting slurry temperature 38-42 degree

8 . body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9 .Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

Specification:

Cement lime fly ash style aerated block raw material proportion

name |

unit |

Cement lime fly ash |

flash |

% |

65-70 |

cement |

% |

6-15 |

lime |

% |

18-25 |

gypsum |

% |

3-5 |

Aluminum powder paste(600kg/m3) |

1/10000 |

8 |

Water & material rate |

|

0.60-0.65 |

Casting system |

OC |

36-40 |

Aluminum mixing time |

S |

30-40 |

11. Cement lime Sand style aerated block raw material proportion

Name |

Unit |

Cement Lime Sand |

Sand |

% |

55-65 |

Cement |

% |

10-20 |

Lime |

% |

20-30 |

Gypsum |

% |

2-3 |

Aluminum powder paste(600kg/m3) |

1/10000 |

8 |

Water & material rate |

|

0.65-0.75 |

Casting system |

OC |

35-38 |

Aluminum mixing time |

S |

30-40 |

Our factory is professional manufacturer of autoclaved aerated concrete (AAC) plants for more than 10 years, and we can supply complete set of autoclaved aerated concrete plant withcapacity of 50 000m³, 100 000 m³, 150 000 m³, 200 000 m³, 250 000 m³, 300 000 m³annually, including plant design, equipments installation, technical support, personal training, etc, and also can design and manufacture as per clients' requirement and so on.

Raw materials: cement, lime, sand (or fly ash), gypsum, aluminum powder, water.

Send Inquiry to This Supplier

You May Also Like

-

Paving Stone Making Machine Cement Hollow Brick Making Machine 2-hole Hollow Brick Making MachineUS$ 1050MOQ: 1 Combo

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece