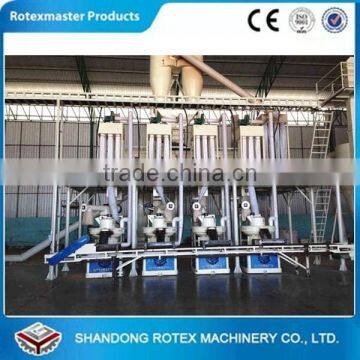

Good Performance Sugar Beet Sawdust Wood Pellet Machine Line, 1Ton/Hour Bagasse Complete Pellet Line

Product Application

Vertical Ring Die Pellet Machine is a new biomass fule production machinery by using crushed

sawdust and bran from eucalyptus,pine,birch,poplar,fruit and agricultural straw, bamboo.

Compared with the old machine,this new vertical ring die pellet machine efficiently.

Rotex YGKJ series vertical ring die pellet machine absorbed the essence of pellet mill in oversea market,after our engineers improved,it had reached the international advanced level.

We just do the best machine,provide best service.We are your best choice.

Main Features

1.Vertical Feeding

This design can feeding the materials into granulating room directly, and avoid jam in granulating room .

2.Double-layer dies

Both sides of the die can be used, and when one side be used up, you can change the other side to continue using. This design increase the availability of die, and reduce cost.

3.Change die Equipment

According to the clients requirement,we make a design for changing the die,and install a lift equipment on the machine, it's convenient for clients to change the die.

4.Cooling System

As the pelletizing process will generate high temperature, it will lower the service life of die and bearing. Cooling system are considering this situation and avoid it happened.

5.Harbin Bearing

All the machines use Harbin brand bearings, which produced by Harbin main workshop, and the best brand in China, good quality.

6.Reducer/Gear Box Brand——GuoMao

For the reducer/gear box, we use GuoMao brand in China, which is a listed company, famous brand and good quality.

7.Siemens Brand Motor

All the machine use Siemens brand motors. high quality

8.Hydraulic Equipment to Install the Main Shaft

We use this hydraulic equipment to install the main shaft of wood pellet machine which is high precision, other supplier may use traditional way to knock it in,it may damage the shaft and bearing of wood pellet machine or have gap inside, after some time, the bearing of wood pellet machine will damage soon.

Shaft chamber material we use cast steel, not cast iron, all material of wood pellet machine is from the professional company, and provide the guarantee for the quality.

9.Automatic lubricating system

Which lubricate the bearing, dies and rollers ,increase the produce efficiency and reduce

energy consumption.It can work continuous 24 hours.

10.Multifunctional usage

Rotex biomass pellet machine could used for making 4mm,5mm or 6mm feed pellets,also,can compress 6mm,8mm or 10mm biomass fuel pellets,double functions,save cost,high efficient.

Double-layer Die.

Ring die materials stainless steel,has been via heat treatment,about 1500h,save cost,high efficiency.

Automatic Lubrication System.

Biomass pellet machine has automatic lubrication system,so make sure the pellet machine work 20-24h without stopping.

Hoisting Equipment.

The pellet machine hoisting equipment used for changing die,save manual and cost,increase efficient.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Biomass Pellet Machine with link

91.8% Response Rate

Drum Wood Chipper with link

91.8% Response Rate

Feed Pellet Machine with link

91.8% Response Rate

Send Inquiry to This Supplier

You May Also Like

-

Pellet Press Machine Soybean Husk Pellet Wood Pellet Machine for Fire Pelets Home UseUS$ 3320.00MOQ: 1 Set

-

China Factory Wholesale 500KW Industrial Electric Silent Power Diesel GeneratorNegotiableMOQ: 1 Set

-

Humic Acid Fertilizer Pellet Machine(CE)US$ 880 - 99,000MOQ: 1 Set

-

Pellet Briquetting Machine / Rice Husk Pellet Mill PriceUS$ 25,000 - 25,000MOQ: 1 Set

-

Wood Pellet Mill Machine for Wood Dust Pellet PressUS$ 1,000 - 10,000MOQ: 1 Set

-

Energy Saving Straw Coal Briquette MachineUS$ 2,000 - 3,000MOQ: 1 Set

-

Diesel Flat Die Small Pellet MillUS$ 500 - 1,000MOQ: 1 Set

-

Industrial Complete Flat Die Wood Pellet Production LineUS$ 20,000 - 25,000MOQ: 1 Set

-

Factory Directly Wood Pellet Press, Wood Pellet Press Machine, Gemco Supply Wood Pellet MillUS$ 3,000 - 4,000MOQ: 1 Set

-

Hot Sale and Best Quality Wood Briquette Machine Screw PressNegotiableMOQ: 1 Set