CE STANDARD HIGH SPEED PE COLUMN EMITTER DRIP IRRIGATION PIPE EXTRUSION MACHINERY

Column emitter drip irrigation pipe extrusion machine

1. Technical specification of flat dripper drip irrigation pipe extrusion line

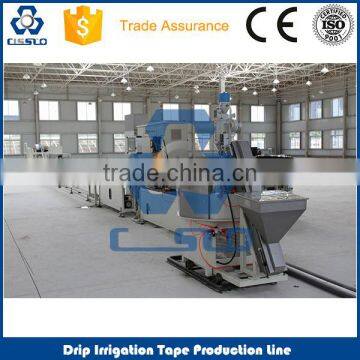

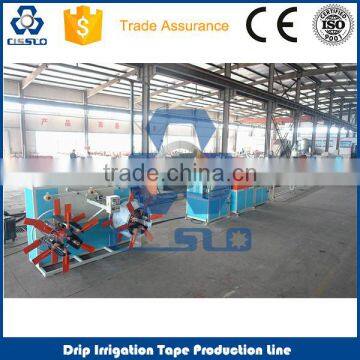

1.1 Pipe Specification:

Pipe diameter | Specifications | ||

Ø12 | Ø16 | Ø20 | |

Pipe thickness | 0.15-0.4mm | 0.15-0.6 mm | 0.15-0.6 mm |

1.2 Speed:90-180m/min

1.3 Center Height: 1000MM

1.4 Installed power: about 135 kW (High speed model )

1.5 Equipment Layout (L*W*H): 25-28* 4..5*3 meter

2. Configuration of flat dripper drip irrigation pipe extrusion line

NO. | Name | Qty. |

1 | Automatic material machine and Mixed machine | 1set |

2 | Dropper recognition, transportation and insert machine | 1set |

3 | SJ60/33 Single screw extruder | 1set |

4 | Cross die head | 1set |

5 | Vacuum calibrating tank | 1set |

6 | Water cooling tank and water removing equipment | 1set |

7 | Automatic Drilling unit (Perforating unit) | 1set |

8 | Haul off | 2sets |

9 | Coiler/winder | 1set |

10 | PLC system and Electrical Control cabinet | 1set |

3. Pictures of flat dripper drip irrigation pipe extrusion line

- New Flat dripper irrigation pipe production Line ( speed l: 150m/min)

Pipe diameter | Specifications | ||

Ø12 | Ø16 | Ø20 | |

Pipe thickness | 0.2-0.4 mm | 0.2-0.9mm | 0.2-0.6mm |

Flat Dripper

- Round Drip Irrigation pipe production Line ( speed l: 80m/min)

Pipe diameter | Specifications | ||

Ø12 | Ø16 | Ø20 | |

Pipe thickness | 0.5-1.0mm | 0.5-1.5 mm | 0.5-1.5 mm |

Column Dripper

- Drip Tape Irrigation Pipe Extrusion Line (speed:. 80-120m/min)

Pipe diameter | Specifications | ||

Ø12 | Ø16 | Ø20 | |

Pipe thickness | Depending on | Customer | Requirements |

Tape Dripper

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 20 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece