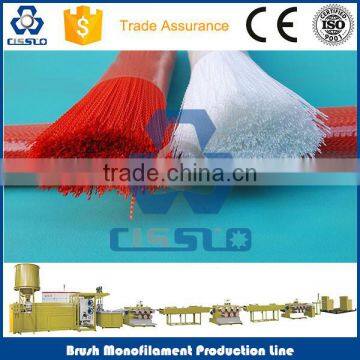

RECYCLED PP PET MONOFILAMENT YARN EXTRUSION LINE

I. Work Condition of Whole Line

Warehouse/Workshop (Provided by customer) | Construction of foundations, construction works, earthworks, and wall works; Supply of cranes, fork-lifts or other lifting equipment; Mounting materials and tools; Dimension (M*M*M): 25(L)×4(W)×3.5(H); |

Power supply | Installed power of whole line: 90kw, Operation power: 54kw Supply voltage: 3*380V+N+PE; Voltage tolerance: +5%/-5%; Control voltage: 24VDC+220VAC; Frequency: 50HZ+-2% |

Wire/cables/water hose: | Wires/cables: From power supply to control cabinet of this production line and all electrical cables from control cabinet to each machine; Water hose: Supply water to machines and pools; |

II. Scope of Supply

No. | Name | Qty. |

1 | SYL-L90×30-580 Extruder | 1set |

2 | Filter, Mould and Melt pump | 1set |

3 | Cooling water tank | 1set |

4 | Seven rollers take-off unit A | 1set |

5 | Hot water tank | 1set |

6 | Seven rollers take-off unit B | 1set |

7 | Oil equipment and winder of waster monofilament | 1set |

8 | Winding unit | 1set |

9 | Setting oven | 1set |

III. Technical Specifications of Monofilament Extrusion Line

1.SYL-L90×30-580 Extruder

1.1 Capacity: Max. 160kg/hr 1.2 Material: PET virgin pellets 1.3 Diameter of monofilament: 0.10-4mm 1.4 Motor: 1.4.1 Type: AC motor 1.4.2 Power: 45kw 1.4.3 Brand: Siemens Beide(China) 1.5 Gear box: 1.5.1 Type: 225, hard tooth surface 1.5.2 Brand: Jiangsu Changzhou 1.6 Screw: 1.6.1 Diameter: 90mm 1.6.2 L/D: 30 1.6.3 Material: 38CrMoALA 1.6.4 Rotation speed: <80rpm 1.6.5 Brand: Zhejiang zhoushan 1.7 Barrel: 1.7.1 Material: 38CrMoALA 1.7.2 Heating mode: Cast aluminum ring |

| Model Parameters | Unit | 760/1010 | 1060/1300 | 1100/1300 | 1300/1300 | 1300/1420 |

| Max.forming area | mm2 | 762*1016 | 1065*1295 | 1120*1295 | 1270*1295 | 1270*1420 |

| (30"*40") | (42"*51") | (44"*51") | (50"*51") | (50"*56") | ||

| Max.forming depth | mm | 127(5") | 127(5") | 127(5") | 127(5") | 127(5") |

| Mould Clamp Force | T | 40 | 60 | 60 | 60 | 60 |

| Max.formingspeed | s/die | 1.8 | 2 | 2 | 2 | 2 |

| Mounted capacity | kw | 110 | 315 | 330 | 365 | 400 |

| Intallation size(L*W*H) | m | 10*2*2.5 | 14*2.2*2.5 | 14*2.2*2.5 | 14*2.35*2.5 | 15*2.35*2.5 |

Our company is established in 1988, specialize in making extrusion equipment, thermoforming equipment and relevant facilities as well as moulds, and it is a limited reliability company which sets development, manufacture, sales and service in one.

We have strong research & development and manufacture ability, and it has a team consisting of professional staff from different engineering fields. Our factory is located in Zhejiang Province of China. We have a team of more than 100 empolyees.

Our machine is with advanced world levels, and its cost performance is incomparable all over the world. The company supplies foaming sheet units, which can produce foaming PE and PS sheet and board. The tandem-foaming machines is mainly making foaming PS sheet and board; Due to various advanced technology, the range foam expansion ratio is very wide and techniques is extremely stable. The single-foaming unit is mainly for PE sheet, and it is simply structured, which is easy for operation with reasonable price.

We are in the lead of thermoforming equipment industry. Its two-station electric thermoforming and trimming unit is set with 6 to 7 servo motors, which can save various kinds of parameters, and have high degree automation and speed. Its forming speed can reach 40 cycles per minute, trimming 160 cycles per minute, and it can process all kinds foaming material and hard

material. One-station thermoforming machine combines forming, punching, and stacking in one machine, which is equipped with 10 to 16 servo motors, and can memorize various kinds of processing parameters. Its forming speed can be 50 cycles per minute. And it can be applied to several kinds of hard material.

Meanwhile, We can provide customer relevant auxiliary parts and moulds, as well as turn-key project service.

Mohamed Soltan,

Sales Manager

CissCo Machinery Co., Ltd.

Mob.: +86 18918321292

Office: +86 2138726398/99

Email: sales@cisscomachine .com

Skype: arab.cisscomachine

Web:

Add.: 30B, No.58 New Jinqiao Road, Pudong, Shanghai, China

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece